Researchers on the Italian Institute of Expertise have developed 3D-printed synthetic muscle mass that convert vitality and indicators into motion and elevate 8 kilograms whereas sustaining human-like hand actions

Corrado De Pascali and his colleagues on the Italian Institute of Expertise have developed 3D-printed synthetic muscle mass, created from actuators that convert vitality into motion by inflating the factitious muscle mass. “We began from the standard synthetic muscle and developed a brand new class of synthetic muscle mass product of a single monolithic part,” says De Pascali.

In line with analysis these tiny actuators that function as synthetic muscle mass may elevate to 1000 instances their weight and this will result in robots with human-like grips. The actuator membranes are referred to as GeometRy-based Actuators that Contract and Elongate (GRACE) and are 3D printed from versatile resin that allows them to stretch and contract like human muscle mass. The researchers designed this membrane utilizing a mathematical mannequin. Some actuators may elevate comparatively heavy gadgets relying on the fabric used to make the actuator and the fabric’s thickness. When put to the take a look at, one 8-gram actuator lifted 8 kilograms.

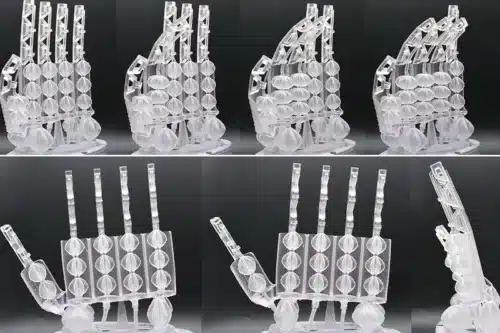

The distinction between earlier generations’ synthetic muscle mass and GRACE actuators is that they encompass pleats of their membrane that may simply fold and unfold offering synthetic muscle mass energy and suppleness. The researchers linked 18 different-sized actuators to make a robotic hand with a wrist. The hand may bend its fingers, twist its palm and rotate on the wrist by making use of strain to the completely different actuator membranes.

“The design of the GRACE is fascinating and novel, offering simple antagonistic operation by design,” says Jonathan Aitken on the College of Sheffield, UK. He believes that one of the vital progressive parts is the selection of versatile resin for the actuator, which supplies a higher vary of motion than the stiffer resins used up till now. Nonetheless, Aitken says this versatile resin may very well be developed even additional. “The extra novel resins that may be developed with wonderful tensile properties will enhance the vary of capabilities of gadgets printed utilizing them,” he says.

Click on right here for an in depth video.