If you find yourself into manufacturing, particularly giga-scale and mega-scale manufacturing, you want sharp visuals and a lightning pace of screening to stop broken units from reaching your clients

SixSense has developed a no-code platform for constructing, monitoring, and sustaining deep studying fashions for laptop imaginative and prescient purposes. Presently, manufacturing engineers utilise the platform to create AI fashions that may detect and classify defects in pictures. They’re shifting from a decade-old inspection course of based mostly on handbook labour or rule based mostly techniques to a considerably extra environment friendly and scalable AI based mostly answer utilizing the SixSense AI platform.

| What occurs when there are a number of inaccurate inspections |

|

• Price of labour will increase |

Visible high quality inspection is among the most crucial processes in manufacturing and is used to regulate the price of high quality. In a 24/7 manufacturing line, visible checks that occur improve the price of high quality exponentially. Right now, inspections have a really excessive error charge of as much as 40%. Producers typically have a crew of operators, who would possibly make errors as a result of components corresponding to fatigue or oversight.

Generally, engineers automate their processes utilizing rule based mostly algorithms. However they fail to scale and adapt to a broader catalogue with delicate variations between defect courses. This results in defects getting missed or false alarms.

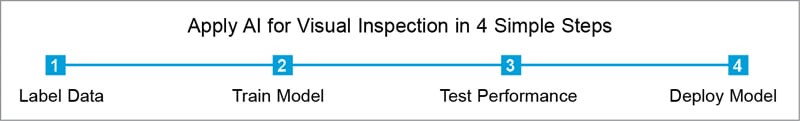

| How does ClassifAI work? |

|

• You may add and label giant volumes of information in a matter of seconds |

“We’ve got recognized this drawback and have constructed an correct AI-powered computerized defect classification software program referred to as ClassifAI,” says Akanksha Jagwani, Co-Founder & CEO at SixSense.ai. “Our know-how integrates with present picture seize instruments, analyses at a really excessive pace, and classifies the defect into varied classes. The AI screens and maintains itself and in the end writes again the category codes of the defects for determination making.” This software program is ready to take any sort of picture knowledge—optical, SEM, X-Ray, and so forth—and analyse it for correct defect classification.