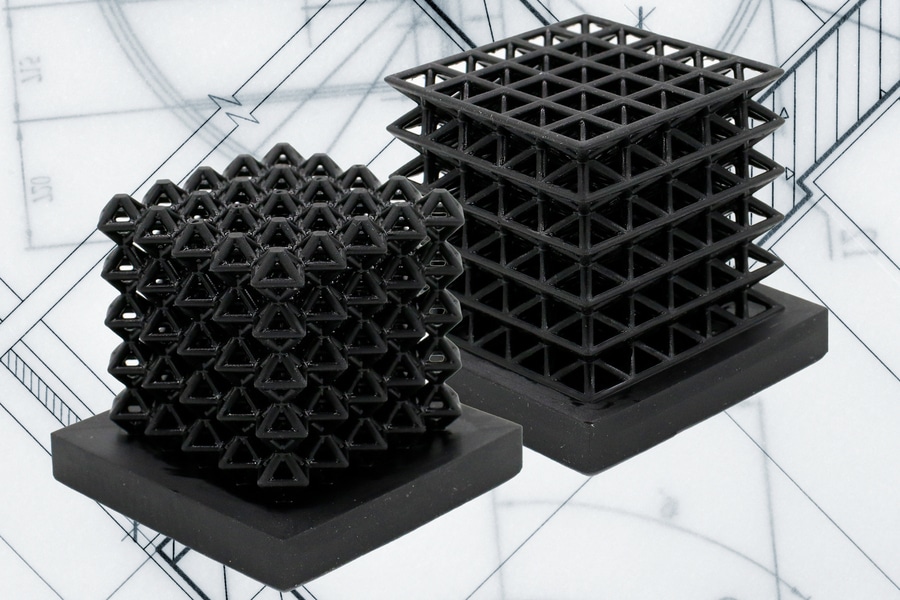

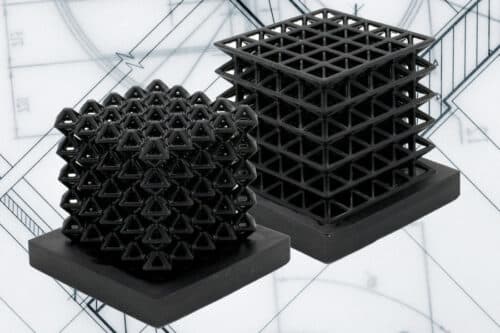

Engineers have developed 3D printed supplies having tunable properties with a community of sensors embedded in it.

Researchers at MIT have developed a way for 3D printed supplies with tunable properties that may sense their very own motion and interplay with the surroundings. This was performed by incorporating a community of air stuffed channels into the construction.

“The concept with this work is that we will take any materials that may be 3D-printed and have a easy option to route channels all through it so we will get sensorization with construction. And should you use actually advanced supplies, then you possibly can have movement, notion, and construction multi functional,” says co-lead creator Lillian Chin, a graduate pupil within the MIT Laptop Science and Synthetic Intelligence Laboratory (CSAIL).

3D printed supplies can possess totally different mechanical properties, however integrating sensors throughout the materials is advanced, contemplating the construction of various supplies. Inserting a sensor on the skin of the fabric will be fairly straightforward however it might not present a exact description of how the fabric deforms.

To sort out this drawback, researchers developed the fabric with air-filled channels embedded within the materials’s lattice itself. When the fabric is deformed and the quantity of air throughout the materials adjustments the corresponding change in strain is measured. This alteration of strain and its readings present the data of how the fabric is deforming.

This materials was developed utilizing the digital gentle processing 3D printing technique. On this technique, the construction is drawn out of a pool of resin and hardened right into a exact form utilizing projected gentle. A picture is projected onto the moist resin and areas struck by the sunshine are cured.

“Sensorizing delicate robots with steady skin-like sensors has been an open problem within the area. This new technique gives correct proprioceptive capabilities for delicate robots and opens the door for exploring the world by contact,” says Senior Creator Daniela Rus.

Researchers expect to find new purposes for this system, similar to creating novel human-machine interfaces or delicate units which have sensing capabilities throughout the inner construction.