Many electrical and optoelectronic gadgets want metal-semiconductor junctions. It may be difficult to make high-quality junctions that combine conventional metals with 2D semiconductors, although they’re now produced and used on a worldwide scale.

A novel method has lately been created by scientists on the Chinese language Academy of Sciences, Hunan College, Metropolis College of Hong Kong, and Fudan College. This system could also be used to extra effectively switch steel electrodes on 2D supplies, permitting for the event of extra reliable metal-semiconductor junctions. This methodology was described in a publication that appeared in Nature Electronics. It includes delaminating steel electrode arrays from a graphene wafer after which printing them onto varied 2D substrates.

“For the primary time, in 2013, we reported that steady graphene monolayers could be grown by way of CVD immediately on semiconducting Ge(001) surfaces, making a major departure from typical metallic programs,” Zengfeng Di, one of many researchers who carried out the examine, informed TechXplore. “Due to the insulating property of intrinsic Ge on the temperature beneath 10K, we carried out the analysis on graphene-mediated superconductivity within the steel nano-islands/graphene hybrid on Ge substrate, with out the switch of graphene from Ge substrate to SiO2 substrate.”

Di and his colleagues found throughout their earlier analysis that metals placed on graphene could also be pulled off fairly readily. This was additionally true for metals like titanium or nickel, that are notoriously exhausting to peel off of silica substrates.

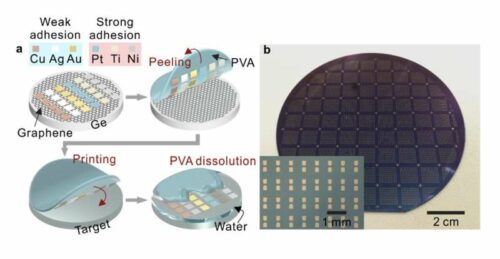

The workforce’s methodology was utilized of their most up-to-date investigation to deposit six completely different steel sorts onto a wafer-scale graphene/Ge donor substrate. This comprised each strongly adhering metals, reminiscent of platinum, titanium, and nickel, in addition to weakly adhering metals, reminiscent of copper, silver, and gold.

There are a number of steps within the researchers’ methodology for integrating steel electrodes on 2D supplies. A steel electrode array should first be deposited on a graphene/Ge substrate. A polymer movie can be utilized to simply peel the array away from the floor of the substrate as a result of graphene has no dangling connections.

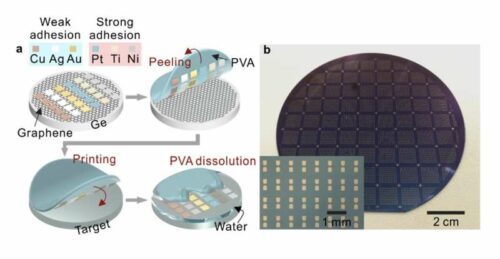

“After eradicating the polymer movie by deionized water, wafer-scale 3D steel patterns can switch onto an arbitrary goal,” Di stated. “In contrast with the earlier switch printing strategies utilizing silica substrate, we are able to switch arbitrary steel with 100% yield and scale up the switch expertise to wafer measurement.”

“Past a easy 2D transistor, we’re utilizing this method to manufacture fundamental 2D logical models, together with AND-OR, NOR, and AND gate,” Di added. “As well as, the price of our method ought to be additional diminished by optimizing the method and growing the reusability of graphene/Ge substrate.”