Xellier Networks, pronounced as ZAY-lier, is an India primarily based firm offering the following technology of high-tech safety options for client areas.

Q. What’s the primary technical downside that you just’re making an attempt to unravel with the product?

A. The massive downside that we try to unravel right here is visible safety. After we consider current safety techniques, we think about a room with a number of cameras in order that we will report if there may be any theft occasion or housebreaking or one thing like that. And the issue with this method is that one must be on a steady guard. One individual is appointed to simply take a look at the screens and interpret what is going on, to simply navigate throughout 30 screens. It’s bodily very tiring and on the finish you can’t maintain the individual accountable in case he missed something. Greater corporations can afford professionals to do the identical however the smaller corporations or companies can’t select to do the identical. Not solely companies however personal properties as nicely.

We thought there wanted some intelligence to be added on this course of and that was our spark. With the event and development of know-how and machines we will prepare the machine to detect and alert if one thing has occurred and inform the supervisor or the one in cost. We purpose to unravel this downside.

“ Automation is a large area and finally the corporate that’s going to face out would be the one who’s working AI into these units.”

Q. How did you include this concept? What’s the story behind Xellier Networks?

A. The story truly begins again once we had been in our closing yr of faculty. We each are engineers and share the identical curiosity. However we had our personal commitments at the moment. We then progressed with our respective lives however finally we got here throughout that feeling to begin one thing of our personal. The idea of entrepreneurship was very taboo at the moment. So later after ten years of job and assembly our commitments once we met in 2018, we shared the identical feeling and frustration.

We wished to construct one thing, so we had a dialogue and commenced with all of the planning. I bear in mind being fascinated by the idea of house automation. We started our analysis associated to house automation and we came upon that house automation is kind of an enormous area in itself. It appeared like solely the large corporations stood an opportunity, as it could be a commoditized product world in spite of everything. The one chance was to give you a really distinctive or innovative know-how.

Dwelling automation requires loads of funding. We can’t simply begin with shopping for an enormous piece of equipment and begin making a sale from it, and finally one product just isn’t sufficient for house automation. One must cowl all features of the house and automate it. So, only a movement sensor or a door opener or a curtain opener/nearer product was not sufficient for the patron. Alternatively, the R&D required is big, except you purchase merchandise from China and resell them right here underneath your individual model.

So once more we had a dialogue on learn how to stand out. We got here throughout one thing on the way forward for automation and AI primarily based houses. And it sparked my curiosity, imaginative and prescient primarily based merchandise are one thing that may stand out. So we started our analysis and stumbled throughout the CCTV applied sciences.

However we didn’t need to construct simply one other CCTV digicam. Chinese language corporations are flooding the market with CCTV cameras, and American corporations however are already growing intelligence in these cameras which we’re planning. Whereas the Indian market may be very tight with primary CCTV cams, though it’s enormous it can’t be coated by these international corporations. This satisfied us to develop an clever safety system for the Indian clients.

Q. How did you construct your first prototype? Are you able to share your product improvement journey?

A. We registered our agency in November 2018, and commenced our engineering analysis on learn how to put collectively our first prototype. Usually, you’d go to a Semiconductor agency and get a reference design, however it didn’t exist at the moment. There was no prepared made resolution that we may simply take and construct our software program on it.

So, we needed to construct our personal reference design from scratch. We put collectively a few of our personal cash that we had saved over time and determined to method distributors to acquire elements. We wrote down options and use circumstances that we would have liked to help in our product and commenced growing it.

Proper from the beginning we had a transparent intention to productize our imaginative and prescient, so we recruited a design agency to assist us visualize our thought and to make sure that our electronics match nicely into the mechanical design. This train took time, however was value it. We used numerous applied sciences like 3D printing, CNC milling and many others. and ran by a number of iterations to visualise our good prototype. It was robust as a result of all this was taking time and costing us some huge cash which we didn’t have a lot. We hadn’t raised any exterior cash, so it was fairly painful. We continued till we had been happy with our prototype.

Q. Are you able to share particulars about what challenges you confronted on this journey?

A. We began with the concept of growing our personal software program on a normal digicam {hardware} platform that we thought we may leverage however we ended up designing our personal reference design. That was exhausting as a result of we needed to speak to many digital element distributors, semiconductor suppliers and lots of didn’t need to help us as a result of we didn’t seem to purchase one million items. Additionally, most of the elements that we use in our product prototype had been additionally not accessible on digital e-commerce web sites. So, we needed to speak, and persuade them to offer us a chance in alternate for no help from their finish. So it was much less dangerous for them. We assured them that we are going to not ask for help so long as their documentations are good. Fortunately, they supported and that mannequin labored for us.

Then the following problem was to productise this prototype that we constructed. That was a complete new recreation through which we had no prior expertise. We needed to be taught concerning the plastics, the supplies, metals, and many others. Many occasions, we needed to contact the fabric provider and ask them primary questions corresponding to, is Polycarbonate higher than ABS? Our design staff was of the opinion to fabricate this product in China the place they’ve the experience and they’d deal with the whole lot. After months of discussions and deliberation, we determined to take quotes from the Chinese language producers. We weren’t that impressed with the pricing. It wasn’t actually that enticing because the hype or the notion we had about china pricing.

We went to the drafting board once more on how we need to scale up and plugged within the numbers to grasp the economics. We understood that China is cheaper solely if you produce in tens of millions and extra. So, we deserted that effort to supply in China and commenced our examine about learn how to produce this product right here in India. We made an inventory of potential injection mould making corporations that we may method and commenced sending them RFQ’s. We hoped that will get an amazing response, however to our shock solely 2 individuals responded. That was very disappointing. We tried to name every one among them over cellphone numbers listed on their web site, Justdial and linked with them by way of numbers listed on Indiamart. Only a few individuals picked up the decision.

We had been shedding endurance by then. We assumed that they don’t seem to be taking us severely, so we determined to drive right down to their places of work in several cities. We took a conventional method, and we personally reached out to the corporate MDs. We instructed them that we’re not middlemen, they’d assumed we’re. We’re the OEMs, we’re producers, we have now a design. We would like you to supply for us since you needed to make the injection mould. So like that it was exhausting to persuade them after which after we obtained their consideration. We had been completely shocked to be taught that the plastics and metallic industries had been so reduce off from the IT world. There was a technology hole between us and them.

In every of our visits to those plastics and metallic fabrication corporations, one factor we understood clearly was that these of us are able to constructing actually complicated elements out of India. And unusually, many of those merchandise are all exported. That studying was sufficient for us to be satisfied that we should produce in India. We satisfied them to take up our undertaking. We didn’t negotiate costs and paid them inside 10 days when the Business customary was Internet 90 days. That’s the worth we paid to get consideration.

Now that the orders had been positioned, our subsequent massive problem was learn how to validate the plastics and mechanical design. It was a problem at a complete new stage that we didn’t anticipate earlier. We spent weeks to months studying learn how to validate the design utilizing 3D modelling, scanning, and CEM strategies. That actually helped. We went by many iterations, which was really-really bodily tiring.

By the tip we obtained our closing injection moulded samples, we had accomplished three years of operation. We nonetheless pushed ahead, continued as a result of we believed within the know-how we had been creating. So lastly in April 2022 we started our gross sales.

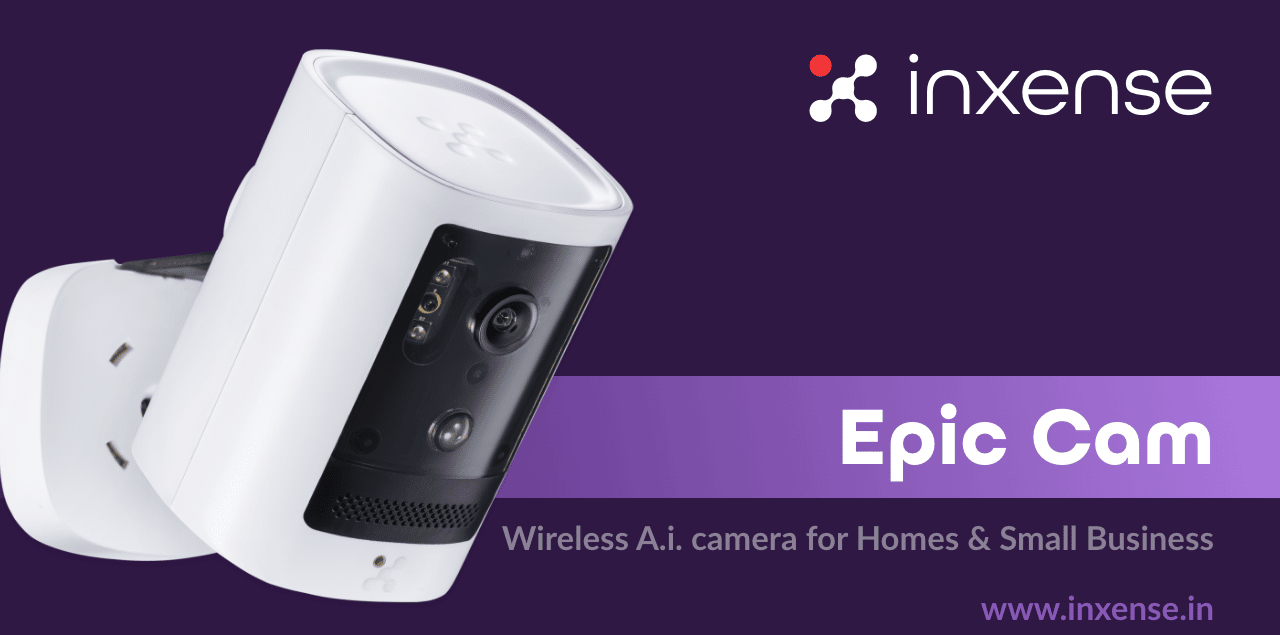

Q. Are you able to spotlight a product that your organization makes a speciality of?

A. One in every of our key featured merchandise is the Epic Cam which is a wi-fi AI digicam. This digicam is constructed on the idea of Sensor fusion primarily for the imaginative and prescient and audio, we even have thermal sensors which attempt to decide about whether or not an individual is transferring or a sure occasion is going on or extra.

We now have a man-made intelligence mechanism that’s constructed contained in the product which communicates with clouds. A mixture of sensors will get some enter and processes it to grasp whether or not there’s a individual in entrance of the digicam and as soon as the digicam is aware of that there’s a individual in entrance of it takes an image of that individual will ship an alert to the consumer together with the excessive decision picture inside two to 3 seconds, wherever he’s on this planet.

Epic Cam additionally helps Automobile and pet detection and alerts you instantly with proof primarily based alerts. After which the client doesn’t have to fret about storage. Video knowledge is definitely heavy knowledge, it goes in gigabytes. We don’t need the client to face any problem so we offer a cloud storage possibility. Clients can instantly hold an eye fixed from their smartphone and obtain it remotely as nicely. The system supplies entry to previous video knowledge even when the digicam is offline. It’s principally a really versatile system.

“We consider that know-how has to adapt to people and never the opposite manner round.”

Q. What are your plans for growth in India and even overseas?

A. At present, we’re focussed on the India market. We’re focussing on strengthening our know-how and making it extra sturdy. Apart from, we’re focussing on advertising and getting the phrase out concerning the product and the providers we provide.