If you’re planning to buy a brand new choose and place machine in your manufacturing unit, listed here are a couple of insights from consultants that would assist you choose the very best machine in your particular requirement.

A choose and place (PnP) machine makes use of complete mechanisms to mount small digital elements and SMDs, similar to capacitors, resistors, and ICs, onto a printed circuit board (PCB). It ensures that the small elements are picked up rigorously and positioned precisely onto the PCB. The machine might be guide requiring placement by hand, semi-automatic with software program help for putting, or automated for typical mass manufacturing models with in-line amenities. Mixed with their respective strengths, listed here are a couple of parameters to think about earlier than investing within the machine.

The PnP machines have significantly improved not too long ago to attain velocity with accuracy, and suppleness. Nevertheless, customary necessities for particular parameters, like accuracy price, element sizes, and board sizes, haven’t modified a lot. The way forward for SMT manufacturing is something however predictable in response to consultants. With quickly altering construct schedules, there’s a proliferation of latest supplies and superior elements to find, load, mount, and hint. As these high-mix challenges go mainstream and mid-volume, actual productiveness and throughput undergo. A number of gear manufacturing corporations try to unravel exactly these challenges.

Allow us to take a look at a few of the options and the challenges so that you could choose essentially the most acceptable machine in your manufacturing home.

Machine building

When deciding on a PnP machine, crucial issue is its building. It determines the machine’s efficient elements per hour (CPH) quantity, footprint, and the variety of element feeders it might accommodate. The development might both be all-welded metal or a bolted-together body.

Essentially the most correct machine might include a welded construction to offer vital stability for correct positioning and high-speed motion in X and Y axes. This fits any manufacturing surroundings with out want for calibration. Aside from this, cautious choice of centering strategies and element positioning programs can help optimisation.

Placement velocity

CPH is the measure at which the machine will choose up and place elements onto the PCB. The velocity measured in CPH could have a direct affect on manufacturing quantity. Many PnP machine producers price their machines based mostly on the IPC 9850 customary, a common information for half combine and PCB placement arrays of their machines. It helps decide the throughput after accounting for feeder modifications, switch time, and different changes alongside the whole meeting course of.

The trade is working in direction of quicker machines yearly to match the elevated velocity demand. Yamaha Motor’s ultra-high-speed modular Z:TA-R YSM40R is among the current launches claiming to supply 200,000 CPH. The velocity is claimed to be achieved by edge know-how, together with modern high-speed rotary heads and linear motors incorporating new, high-speed algorithms, with the machine width of only one metre.

Juki Corp’s RX-8 is one other current launch that claims to have the very best placement price per sq. metre with CPH as much as 100,000. It’s compact and modular, that includes 998mm width. The brand new P20 placement head, designed for putting ultra-small chips and small built-in circuits (ICs), is credited for high-speed selecting and putting from the one reel.

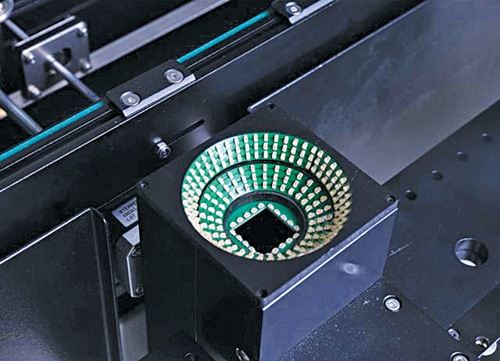

Clever digicam programs

A digicam system with excessive decision improves the general velocity of the machine. New machines concentrate on their digicam programs, just like the one within the Neoden 8 PnP machine. It comes with the HR Flyvision digicam system for element recognition and Double Mark cameras to succeed in the intense finish feeders for higher calibration.

Part dealing with

The PnP machines deal with the minimal and most element dimensions in response to the manufacturing wants for chip-scale bundle (CSP), ball-grid array (BGA), and different odd components. The machines want varied alignment strategies to deal with such a spread of elements, say, from minimal sizes of 0402, 0201, or 01005. Tiny elements smaller than 0402 might require further nozzles. The machines with single alignment give extra precision and velocity. Another alignment system can deal with giant element sizes.

Nevertheless, one ought to bear in mind, not all machines that may deal with giant elements also can examine them. Therefore, many of the new launches with the newest imaginative and prescient system and software program can tackle every thing from 01005-size flip chips and CSPs to giant quad flat packages (QFPs) and ball grid arrays (BGAs). Even tall, odd-shaped and through-hole elements might be mounted with ease.

For example, ASM Meeting Programs has a whole answer from element pickup, picture recognition to placement of odd-shaped elements. Its Siplace TX fashions are stated to work with as much as 48,000 CPH with minimal 0201 (metric) and most element dimension of 8.2mm×8.2mm×4mm.

Variety of choose up heads

A PnP machine has single or multi-heads to seize completely different shapes and heavy components. Geared up with a lot of nozzles to understand the elements, the top is movable in numerous instructions concurrently to make sure excessive productiveness and suppleness.

For example, the Yamaha YRM20 comes with a rotary RM head that’s claimed to attain 115,000 CPH. It contains a one-head answer that may carry elements of wierd shapes and eliminates the necessity for head replacements, thus enhancing the element feed velocity.

Equally, the Neoden 8 mannequin has eight synchronised nozzle heads to offer repeatable placement accuracy.

Good feeders

Latest machines focus additionally on the feeder capability. The bigger elements might require bigger feeders. So, it’s advisable to determine the variety of slots wanted for bigger tape feeder varieties, say, from 4mm to 56mm.

Mycronic MY300 has an ‘clever feeder’ answer that’s claimed to take lower than ten seconds of loading time. Agilis tape and stick feeders and tray dealing with programs within the machine are stated to deal with a variety of elements to satisfy the wants of as we speak’s SMT manufacturing grounds. The compact 4, 8, 12, and 16mm Agilis tape feeders include an modern cover-tape separator on the pen-sized feeder that exposes elements for straightforward selecting. The feeders present amount and placement monitoring, operator steerage, simplified information entry, moisture delicate gadget (MSD) dealing with, and on-the-fly changeovers. Totally operator-independent, it ensures greater productiveness in a smaller footprint. Its product set-up time is one other necessary characteristic for fast processing.

With the SMT measuring feeder characteristic in place, there isn’t a must measure supplies manually, which improves the effectivity and avoids the incidence of fabric error. The current machines characteristic element verification earlier than placement to make sure the correct element is positioned on the proper location and comes with RCDT (resistor, capacitor, diode, and transistor) measurement instruments. Neoden 8 options pneumatic feeders.

Part lead pitch

Business consultants think about 0.012 positive pitch as an unsaid thumb rule for choosing PnP machines. The element lead pitch is the space between the centres of the leads. Nevertheless, consultants warn consumers to not be moved by motor specs or accuracy as even machines with nice motor accuracy might not choose up, examine, and place fine-pitch elements.

Good bin system

The commonest purpose for unplanned downtime in high-mix electronics manufacturing is lacking materials. A sensible bin system helps machine operators minimise downtime by making certain that each one wanted materials is collected and ready just-in-time for manufacturing. Constructing on different highly effective materials dealing with options, the system brings ease-of-use to the kitting and changeover course of. The tip result’s quicker changeovers and better utilisation.

Subsequent-generation precision

The most recent pick-and-place options mix inflexible machine body, superior mount head know-how, and automated thermal adaption for the very best ranges of precision. The MY300 provides an improved line scan imaginative and prescient system to take this accuracy into the following technology. It combines three programmable mild sources with both 2K or 4K decision to make sure a future-proof answer for essentially the most superior elements right down to 0.15mm pitch. Each choices present extraordinarily exact on-the-fly positioning and inspection for any kind of miniaturised or specialised element

Accuracy and repeatability

Specialists’ candid advice concerning accuracy for PnP machines is 0.00254mm (0.0001-inch) with a positive pitch lead of 12mil repeatedly. Although such excessive accuracy is often characterised for high-budget machines, one can all the time discover a used PnP machine to realize such outcomes. In addition to, bear in mind to purchase a machine that comes with software program suites to deal with the method.

That includes a single turret head with eight or twelve nozzles, Europlacer’s ii A1 mannequin is claimed to ship flexibility in dealing with a broad vary of elements with 164 feeder positions and two inside matrix trays, all in a compact footprint. It additionally options the agency’s patented clever conveyor with board stops underneath full software program management.

Software program suite

If you’re contemplating buying automated machines, how are they programmed and what are the software program used ought to be answered. The software program has three main targets of straightforward use, flexibility, and optimising efficiency.

No matter, bear in mind to examine in case your mannequin comes with a pc or simply the software program. This may neither be good nor unhealthy as some customers want to put in the software program on their very own PCs. A totally built-in system is your best option to keep away from software program compatibility points, nevertheless.

Additionally examine if the machine runs on a well-recognized graphical consumer interface (GUI), similar to Home windows, or a proprietary system. Most operators want a normal GUI since a proprietary GUI might require an extended studying curve. CAD obtain, instructing digicam, barcode readers, administration data system (MIS), and optimisation features and off-line programming can all make the operator’s job straightforward and environment friendly. Therefore, a powerful software program suite is necessary to make the method straightforward and traceable.

For example, DDM Novastar provides a singular programming software program—SMTrue Run Optimise—to the full-scale SMT meeting providers it affords. The software program is used for making offline programming of automated SMT machines to derive elevated effectivity and throughput.

ASM Meeting System additionally has IIoT interfaces for integration into line and manufacturing unit programs (ASM OIB, IPC-Hermes 9852, IPC-CFX) and the cloud (ADAMOS) with superior workflow options for setup processes, materials administration, manufacturing unit monitoring, and manufacturing unit integration.

The brand new machines are additionally utilizing quite a lot of open supply software program. OpenPnP is an open supply SMT choose and place system that features ready-to-run software program and {hardware} designs which you can construct and modify. Index PnP is an open supply pick-and-place machine that’s among the many current launches designed for mass-production volumes typical of crowdfunding tasks.

Different necessary issues

Populating extra boards and machines which are match for any clever manufacturing unit, full with absolutely automated materials stream, quicker changeovers and open interface software program is the true pursuit of the trade. There is no such thing as a restrict to the trivialities of pick-and-place machine specs. You might have to pick out the options as per your wants.

In contrast to the fast placers, precision placers usually don’t use mounted nozzles. They might depend on gantry-supported transferring heads with comparatively few pickup nozzles. Whereas the standard four-head vertical heads had been solely out there in table-top machines, now they’ve advanced into automated machines.

Some machines might need to optionally be fitted with a dispense head for depositing adhesive on the board. In the event you require this characteristic, think about the dispense technique, dot dimension, and dispense velocity.

Most and minimal PCB or panel dimension and thickness might be essential necessities for some producers. Fiducial recognition, coordinate correction, and unhealthy mark detection ought to be customary for any automated PnP machine.

New machines have a 3D stereo measurement characteristic for the through-hole gadget that simply identifies the picture of the vertical pin and top of the element result in detect bending deformation. This tells whether or not the through-hole elements are positioned precisely to make sure the right top after placement, and thus reduces the necessity for operator’s visible inspection. Equally, sample characteristic recognition is one other side supposed for particular elements to recognise irregular placements and guarantee accuracy.

Specialists additionally attempt to discover the very best acceleration. In lots of circumstances, the acceleration of huge elements is ready manually. Latest upgraded machines can robotically detect and speed up to make sure the standard of placement and maximise the utilisation of kit.

The following concept catching up is of PCB placement inspection. Earlier than beneficial elements, similar to BGAs and land-grid array (LGAs), are positioned, interfering object detection is carried out within the placement space under these elements. The international materials/components in extra are present in time to keep away from placement defects. This may examine whether or not there are any lacking elements underneath the shields earlier than they’re positioned, which can play an excellent protecting function in enhancing product high quality.

The automotive electronics trade is anticipated to extend the demand for SMT repeatedly. Contemplating that automotive merchandise have greater necessities for private security, service life, and out of doors use circumstances, the reliability and sturdiness wants of automotive digital merchandise are greater than these of others.

New PnP machines characteristic applied sciences like auto-cut sensor and superior sensor applied sciences. Auto-cut sensor know-how is a human security characteristic that briefly stops the method to keep away from critical hazards or machine injury on human intervention. Superior sensor know-how helps a selected set of sensors, like in-sensor, out-sensor, and ready sensor, in monitoring the PCB at each stage within the manufacturing course of.

Auto-optimisation is one other characteristic to think about as it might recommend feeder and nozzle measurements. There’s additionally a characteristic known as common automated detection for nozzles. The closed-loop management of the nozzle ensures that the nozzles on the position head are all the time in a standard clear situation, and the contaminated and broken nozzles are robotically changed in time.

Selecting the very best

The most recent technology of the position machines units new information in velocity, floorspace efficiency, and accuracy for high-volume manufacturing functions. Good manufacturing unit options are quick turning into a development within the electronics manufacturing trade to chop down on prices and enhance effectivity of manufacturing.

Nevertheless, consumers ought to take note of efficiency and value in relevance to their manufacturing wants. Machines can be found in varied worth ranges with a variety of buyer help and upkeep. Maintaining in thoughts the funding on machine is important to keep away from spending a fortune on pricey outsourced machines.

Whereas the traditional PnP imaginative and prescient programs are tough to work in areas requiring manufacturing tolerances and deviations, Schubert Group—an organization creating modular packaging machines—suggests its neuronal networks based mostly on synthetic intelligence may very well be an answer of the longer term. “The picture processing system subsequently learns by itself and types the merchandise into courses independently in an extended studying course of. Because of this the parameters are chosen by the system and now not by the programmer. For purchasers, this implies a big step in direction of independence—Sooner or later, they might truly use neuronal networks, underneath sure circumstances, to show their packaging machine to deal with a brand new product by itself,” writes Dr Abdelmalek Nasraoui on the corporate web site.

Abbinaya Kuzhanthaivel is a technophile at EFY with an curiosity to put in writing on electronics, communication networks, and open supply