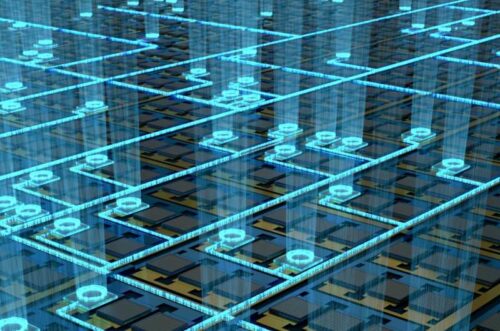

In-sensor picture processors with a number of voltage-tunable photodiodes can filter pictures as they get captured.

Accidents occur in a blink of an eye fixed. Contemplating the development from handbook driving to autonomous driving, priorities for security will increase. Now, in terms of the digicam system in autonomous automobiles, processing time is vital. The time consumed for the system to snap a picture and course of it might imply the distinction between avoiding an impediment or moving into a serious accident.

In-sensor picture processing, which extracts vital options from the uncooked knowledge itself as an alternative of a seperate microprocessor can tempo up the visible processing. Researchers on the Harvard John A. Paulson College of Engineering and Utilized Sciences (SEAS) have developed the primary in-sensor processor that could possibly be built-in into industrial silicon imaging sensor chips – CMOS picture sensors.

“Our work can harness the mainstream semiconductor electronics business to quickly carry in-sensor computing to all kinds of real-world purposes,” stated Donhee Ham, the Gordon McKay Professor of Electrical Engineering and Utilized Physics at SEAS and senior creator of the paper.

Researchers developed an electrostatically doped photodiode array. Because of this the sensitivity of particular person photodiodes, or pixels, to incoming mild will be tuned by voltages. An array that connects a number of voltage-tunable photodiodes collectively can carry out an analog model of multiplication and addition operations central to many picture processing pipelines, extracting the related visible data as quickly because the picture is captured.

“These dynamic photodiodes can concurrently filter pictures as they’re captured, permitting for the primary stage of imaginative and prescient processing to be moved from the microprocessor to the sensor itself,” stated Houk Jang, a postdoctoral fellow at SEAS. The array will be programmed into completely different picture filters to take away pointless particulars or noise as per the purposes.

“By changing the usual non-programmable pixels in industrial silicon picture sensors with the programmable ones developed right here, imaging gadgets can intelligently trim out unneeded knowledge, this could possibly be made extra environment friendly in each power and bandwidth to handle the calls for of the subsequent technology of sensory purposes,” stated Jang.