A DIY non-contact digital tachometer for machinists

— September twenty third, 2022

A tachometer is a tool that counts the revolutions of a rotating object, with probably the most well-known instance being the automotive tachometer that displays the revolutions per minute (RPMs) of an inner combustion engine. However tachometers are helpful, and generally a requirement, in lots of different functions. RPM is a vital datum when working with machine instruments like lathes and milling machines, which is what this DIY non-contact digital tachometer was designed to accommodate.

The time period “feeds and speeds” refers back to the parameters a machinist makes use of to realize the perfect software load. A vertical milling machine’s finish mill, for instance, can solely take away a specific amount of fabric with every stroke of every chopping flute. For that cause, it’s crucial {that a} machinist know the way quick the top mill is rotating. Most trendy machine instruments (not simply CNC instruments, but in addition guide instruments) embrace a digital RPM show. However many older machines and a few trendy machines with low-cost VFDs (variable-frequency drives) don’t and that makes it very troublesome to keep up optimum load. This DIY system addresses these shortcomings in an inexpensive method.

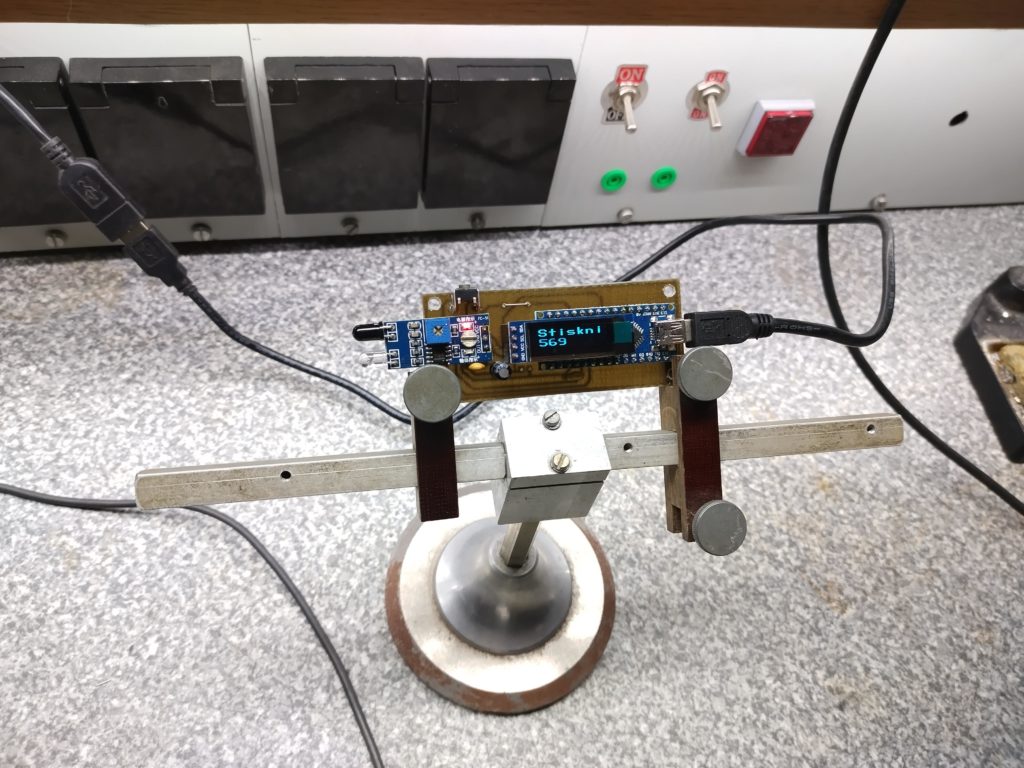

Inside the system’s 3D-printed enclosure are an Arduino Nano board, an infrared distance sensor module, a 0.91” 128×32 OLED display screen, a lithium-ion battery, and a TP4056 lithium battery charging module. Any time the infrared sensor sees a powerful reflection of its emitted mild, it counts a pulse. However timing the delay between pulses, the Arduino can calculate the RPM after which show that quantity on the OLED display screen. The person solely must mount the system in entrance of the item to watch, like a mill’s spindle or a lathe’s chuck, and put a 6mm-wide piece of white tape in entrance of the infrared sensor. Each time that white tape passes in entrance of the sensor, it displays loads of mild for the sensor to detect as a pulse.

This doesn’t require any bodily modification of the machine software, as a result of it runs on battery and doesn’t have to make bodily contact with the spindle, so it’s good for machinists engaged on an employer’s tools.

You’ll be able to observe any responses to this entry by the RSS 2.0 feed.

You’ll be able to go away a response, or trackback from your individual web site.