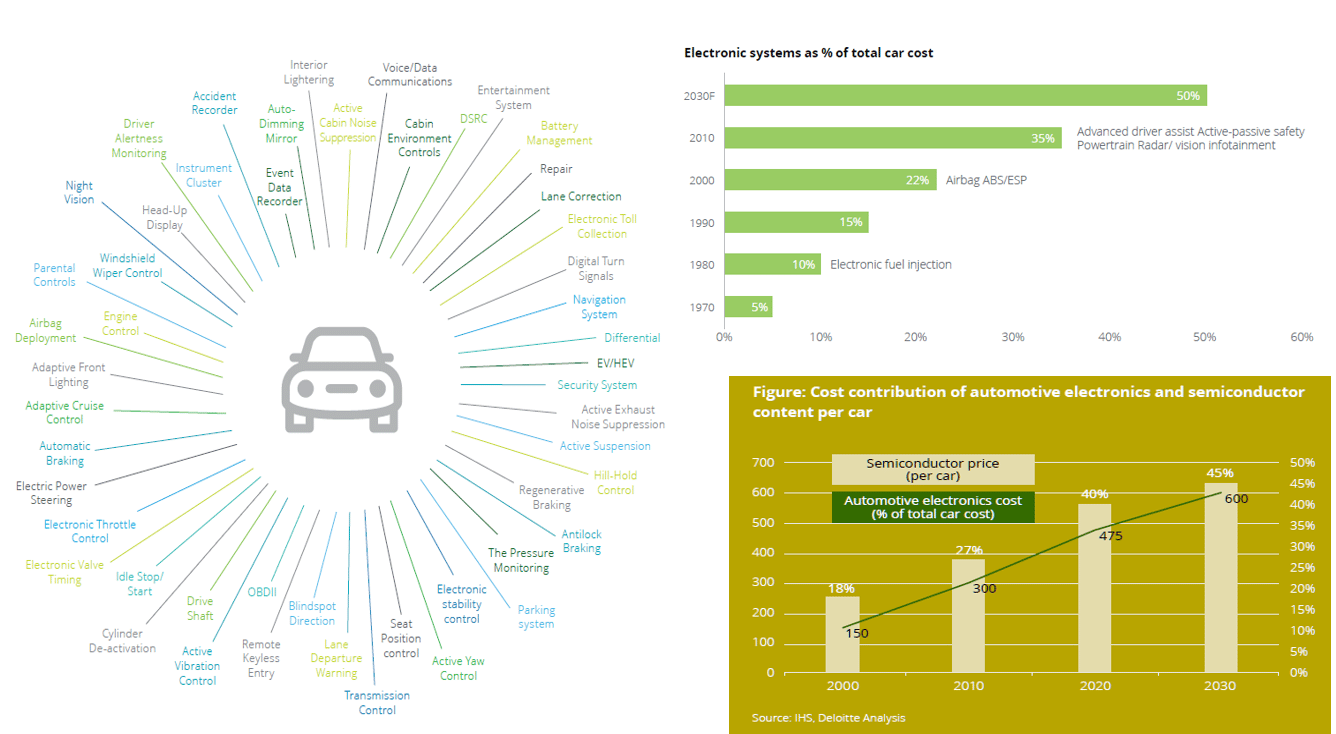

There’s a rising share of electronics in a automobile, starting from infotainment, physique, and engine controls to superior driver-assistance modules. At present, premier automobiles have as much as 70 MCUs (Microcontroller Management Items), interconnected by a number of system buses, and trade 1000’s of indicators between themselves. To place that in a enterprise perspective, analysts estimate autonomous chips’ annual income to develop from $11 billion (in 2019) to $29 billion in 2030, representing income of $350 per car by 2030 [1]

The rising variety of electronics in autos permits efficiency enhancement, higher security, and safety together with different value-added options. With the elevated complexity of digital elements together with cameras, radars, sensors, and so forth, you will need to put enough emphasis on their reliability. A single malfunction of an digital part can result in a life-threatening state of affairs.

Semiconductor firms supplying the digital elements topic them to rigorous testing for any useful or manufacturing defects.

Machine testing is a well-established course of, that requires particular design exercise as a way to insert correct take a look at infrastructure within the die, with the help of devoted EDA software program. It Is categorized as Design for Check (DFT) or extra typically as DFx, to incorporate different manufacturability, reliability, and yield elements. Nevertheless, an automotive microcontroller unit (MCU) poses extra challenges and constraints on the testing mechanism, in comparison with communication, networking, or leisure domains.

On this article, we offer an outline of those distinctive challenges and testing options deployed.

Automotive Testing Challenges Overview

1. Mission-critical utility

Automotive unit is a life-sensitive utility, each for individuals inside in addition to outdoors the car, thus there isn’t any room for an error. We will very nicely think about the affect if the airbags don’t get deployed on the proper time! The extent of acceptable defects is expressed by DPPM (Faulty Components Per Million) and Automotive Security Integrity Ranges (ASIL) outlined below ISO 26262. Whereas for a consumer-grade system, a DPPM variety of ~300 could also be acceptable, for automotive it must be near zero!

Thus automotive MCU requires a really excessive take a look at protection and it is not uncommon apply to check virtually all design nodes by way of structural stuck-at (SA) and transition delay(TD) checks. The necessities are barely relaxed for typical consumer-grade units. It’s price mentioning right here that gaining simply the final 0.1% protection, takes vital design efforts and a whopping variety of take a look at patterns, thus including to the take a look at time and take a look at price. Additionally, as a way to cowl all forms of potential defects in automotive units, new fault fashions are constantly explored and added to the take a look at fits, eg, cell-aware, bridging, and small-delay-defect checks.

Along with the manufacturing facility testing, the units are commonly screened for any defects that will have crept in through the working lifecycle. Crucial logic and recollections are fitted with a self-test functionality utilizing LBIST and MBIST respectively, that will get triggered at system booting, shutdown, or at common intervals. The outcomes are monitored by utility software program and any concern will get raised as an acceptable alarm within the system.

Self-test, nonetheless, brings its personal design overheads when isolating the take a look at logic from exterior interferences to make sure that the performance will not be disturbed, prevention of unknown states (X-sources) to keep away from corruption of signatures, and test-point utilization to extend the controllability and observability of the design.

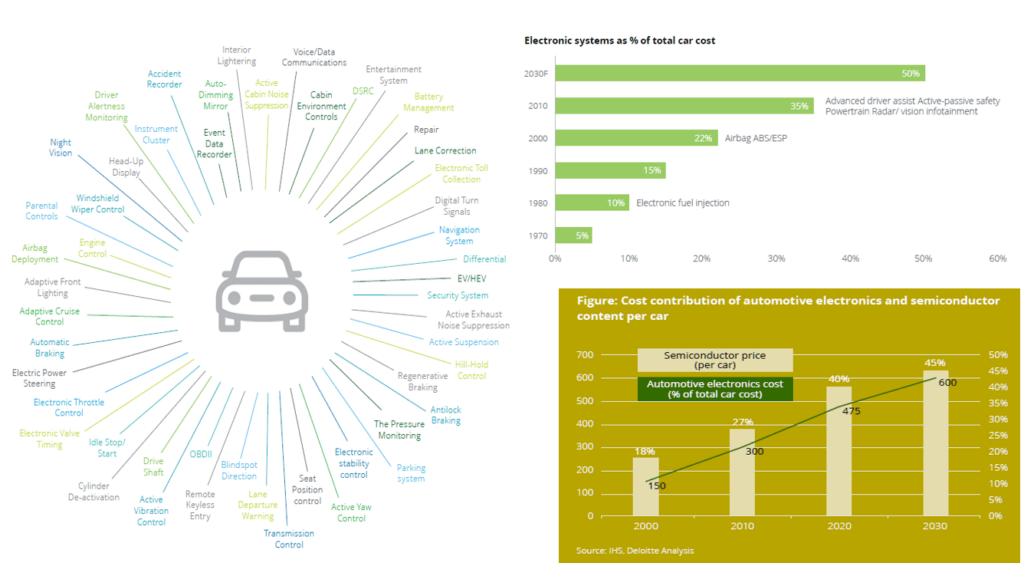

The first goal of any self-test approach is to detect in-field failures, therefore the execution time required for such methods will be very stringent. Any fault ought to be detected in a specified time known as DTI (Diagnostic Check Interval) in any other case it could actually show to be catastrophic for the whole system. This makes self-test implementation like LBIST an uphill process. As a result of random nature of the Logic Constructed-In-Self-Check (LBIST) engine, generated by on-chip PRPG (Psuedo Random Sample Generator), it’s generally very difficult to get the required fault protection within the allotted time. This calls for large take a look at level insertions within the design to enhance the controllability and observability for random resistant and hard-to-detect faults. Whereas this step has been non-obligatory for regular ATPG testing, it’s completely important for LBIST. Check factors are inserted for hard-to-detect faults, which often occur to be in logic with deep combo depths and therefore timing vital paths, which pose their very own challenges through the backend implementation

Fig. 2 reveals the rigorous train completed to achieve the specified run instances for LBIST in two vital IPs for an ST automotive chip. IP1 is a fancy design having very excessive combinational depths. A number of iterations with the CAD vendor to reinforce the take a look at level insertion algorithms resulted in attaining the required take a look at time and protection aim. Nevertheless, a couple of designs like IP2 which achieved the take a look at time aim with enhanced take a look at level insertion circulation, created an antagonistic impact on timing, as many management factors had been added on the vital useful paths. Thus, offering a self-test function in automotive chips is usually a very iterative and interesting course of, with so many conflicting necessities for the DFT engineers.

2. Vast atmosphere vary, -40 to +150C temp

A automobile is anticipated to work seamlessly when driving from the snow-laden mountains proper into the scorching desert or into the humid rainforests. This places a variety of strain when signing off the system throughout temperature extremes. The testing additionally must cowl these excessive nook situations but keep excessive manufacturing yields. Automotive qualification contains testing the techniques at areas with excessive and opposed situations like Finland in Winter or Morocco in Summer time, and so forth. to validate the working vary.

Automotive DFT structure is designed to deal with die-to-die and on-chip variance ensuing from manufacturing course of parameter variations, along with an excessive temperature vary. The resultant affect to setup and maintain timings on design paths, throughout a shift in addition to seize section of scan-based testing, are dealt with by way of devoted and sturdy design constructions. That is sometimes not a necessity for consumer-grade merchandise the place the ambient temperature vary is roughly 0 to 85C.

The library characterization, analog fashions, and design sign-off additionally must cater to those elevated variations and extra margins. That is additional aggravated by system growing older. As an illustration, Fig 3 depicts how delays get impacted resulting from variations throughout PVT (Course of, Voltage, Temperature) and ageing. Excessive left on the determine is the reference delay with regular (typical) parameters and subsequent curves present how the delays get skewed with altering parameters.

Machine qualification entails samples which might be particularly manufactured at completely different course of corners (known as matrix heaps) after which examined at each supply-temperature situation. Particular circuits, eg on-chip course of screens, are added to every unit to determine the system conduct and to tune (or trim) regulators, oscillators, and different vital elements accordingly. The information is collected over a lot of samples to determine any course of drift and to fine-tune the manufacturing, as wanted. Scan strategies and yield analyzers are leveraged closely to extract, diagnose and course of such knowledge.

![PVT variations for 300 paths on an ST device at 28FDSOI process [2]](https://www.electronicsforu.com/wp-contents/uploads/2022/10/Screenshot-7-500x307.png)

3. Prolonged Lifetime – 15yrs

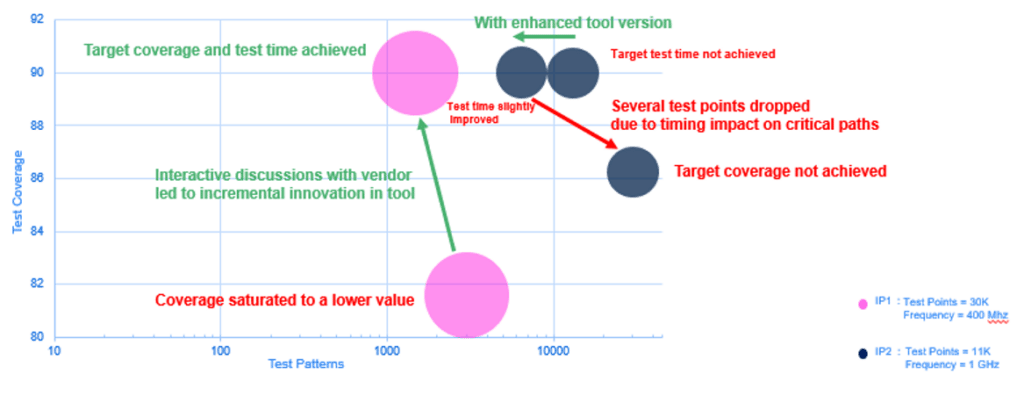

An MCU within the automobile is required to serve for the whole working lifetime of the automobile, sometimes 10-15yrs, without having any service or substitute. Fig 4 reveals typical failure charge change over time. The system qualification must account for ageing, long-term reliability, and early failure detection.

Each automotive unit is run by way of stress checks (BurnIN, HVST, VLV, and so forth), in contrast to many shopper purposes the place just a few pattern items are topic to emphasize checks. The aim of stress checks is to push any weak part to fail upfront, slightly than fail within the area.

A few of the ageing manifestations are NBTI (Adverse-bias temperature instability), Sizzling Provider Injection (HCI), and Time-Dependent Dielectric Breakdown (TDDB) results [3]. These are sometimes screened by way of HTOL (Excessive Temp Working Life) stress and extra Vmin/Vmax margins through the take a look at. For brevity’s sake, we are going to skip delving into the small print. Nevertheless, these checks additional push the design and take a look at limits. For instance, testing at Vmin of 0.9V, whereas additionally accounting for tester-equipment uncertainties and on-chip volt-drop, the tip nodes of a path might finally get a voltage under the signoff Vmin. Couple this with PVT parameters and we could also be headed at throwing some in any other case good units (yield affect). We sometimes add sign-off guard bands and extra robustness on scan construction, particularly on hold-sensitive shift paths, to keep away from such losses.

Silicon Lifecycle Administration (SLM) is one other rising paradigm, as a way to keep the system reliably obtainable all through the working lifecycle [4]. SLM leverages take a look at infrastructure, along with different sensors like in-situ screens, to detect and handle points whereas in-field. The presence of those extra constructions provides to check overheads and requires a singular answer at every layer. For instance, in-situ cells are custom-made to completely scan-test the monitoring websites, along with the useful nodes.

Useless to reiterate that the majority shopper purposes are exempt from such rigorous checks.

4. Standby operation

Sure sensors and management domains stay powered up all through, even when the ignition is off.

These units draw energy from the battery within the automobile and therefore are required to maintain the facility consumption to a naked minimal. We would definitely be upset to see the battery all drained and unable to self-start, after parking the automobile for 2 weeks within the storage!

Many automotive units, particularly physique purposes, are designed with a number of power-domain islands; which generally have impartial voltage ranges as nicely.

The take a look at structure is designed to deal with isolation checks, energy controllers, standby operations, and so forth. A number of provides additionally want consideration throughout low-pin-contact testing.

Networking, server, and gaming purposes stay powered with an electrical energy supply, and therefore don’t require such low-power designing.

5. Safety and security hardening of take a look at logic

Check logic has been demonstrated as a useful gizmo to extract system secrets and techniques from adversaries. A automobile within the area incorporates many secret keys and codes, from chip producers, OEMs, customers in addition to third get together distributors. Entry to those property imposes monetary losses in addition to threat on the roads (each for the consumer in addition to individuals across the automobile) if misused. A tool might comprise delicate knowledge from the consumer, chip vendor in addition to third get together answer suppliers. Hacking or manipulating a rented automobile might put the following consumer in danger or at ransom!

Structural logic, like scan chains, is proven as a straightforward instrument to learn out system secrets and techniques. Thus it is important that take a look at logic is robustly disabled and can’t be used to launch an assault or learn any system secrets and techniques [5], even below diagnostic or fail-return eventualities,

On the similar time, take a look at logic can be leveraged to determine any malicious logic or Trojans on the system, inserted through the design or manufacturing course of.

Along with safety, take a look at indicators additionally must be security compliant. Any smooth error (SET/SUT) in take a look at logic can’t be allowed to affect the system performance and put it into an undesirable state. Varied obfuscation methods in addition to redundancy logic (e.g Triple Module Redundancy) are positioned on the take a look at logic and enablement paths to cater to safety and security necessities.

6. Quantity economics

Automotive qualification and certification is a protracted, rigorous, and costly course of. So a tool, as soon as certified, is used for a number of years, earlier than being upgraded to a brand new model. Automotive producers would deploy a single certified product throughout a number of fashions for a few years. Automotive chip distributors must maintain their design, fabrication, and testing amenities for an extended interval for a single product. All amenities must constantly carry out on the similar parameters on which the system was certified, with none deviations, thus including to the upkeep prices.

This locations the automotive MCUs right into a high-volume, low-margin bracket in comparison with shopper markets. A lot in order that ‘Automotive grade’ units are generally known as ‘military-spec merchandise at shopper costs.

The ensuing income strain pushes greater multisite and low-cost-tester options, thus including additional complexity to the take a look at structure and execution.

Conclusion

We talked about among the distinctive wants and challenges confronted by automotive chips and related complexities whereas testing these units. The testing neighborhood has put particular structure and methods in place, and are continuously evolving, as a way to guarantee a protected, safe, and dependable drive on the roads. It actually impacts the system and cycle-time prices, however as somebody stated – if you happen to discover testing costly, strive with out it!

References:

[2] Investigation of Crucial Path Choice for In-Situ Displays Insertion, 2017 IEEE twenty third Worldwide Symposium on On-Line Testing and Strong System Design (IOLTS)

[3] https://semiengineering.com/circuit-reliability-verification-for-automotive-electronics

[4] https://www.synopsys.com/options/silicon-lifecycle-management.html

[5] X. Li, W. Li, J. Ye, H. Li, and Y. Hu, “Scan Chain Primarily based Assaults and Countermeasures: A Survey,” in IEEE Entry, vol. 7, pp. 85055-85065, 2019