Whilst designers’ creativity comes alive with 3D-printed garments and jewelry at a trend present, elsewhere on the earth a cancer-ridden hen stays alive with a 3D-printed invoice, and a new-born little one will get a brand new lease on life with a 3D-printed cranium. Certainly, the rising functions of 3D printing are awe-inspiring and full of hope

Crescent, a 25-year-old Nice Indian Hornbill, is among the most cherished birds in ZooTampa at Lowry Park, Florida (USA). When the zoo officers posted an image of this winged magnificence on their Instagram web page final yr with the tag line, “Crescent, our Nice Indian Hornbill by no means misses an opportunity to strike a pose. Come out and go to her in our major aviary…,” little would they’ve thought that she can be inflicted by a probably deadly type of pores and skin most cancers referred to as squamous cell carcinoma.

Whereas the tumour is often discovered close to the entrance of the casque in hornbills, hers was within the again. This nearly dominated out the opportunity of a conventional extraction, as it could have uncovered the hen’s sinuses. So, a staff on the College of South Florida’s Radiology division printed a brand new casque utilizing a Formlabs 3D printer and their new BioMed White Resin, a photocurable materials that can be utilized to print biocompatible elements for prosthetic gadgets.

The fabric had simply been developed by Formlabs, and so they donated it to the staff making an attempt to assist Crescent. The staff not solely printed a brand new casque but in addition a reproduction of Crescent’s head in order that the staff of veterinary surgeons might attempt the operation just about earlier than performing it on the hen—because it was a uncommon process, which had been performed solely as soon as earlier than by a veterinary surgeon in Singapore.

In January this yr, the staff eliminated the tumour and fitted the brand new casque on Crescent, who’s now again within the aviary—as perky as ever. Fortunately, it turned out that the resin was an ideal match for the yellow preening oils that hold a hornbill’s casque vivid and glossy, so she additionally seems as fairly as ever!

As towards the early days of 3D printing, or additive manufacturing, when objects may very well be created solely with a number of polymer based mostly supplies, we now have superior processes that allow 3D printing with dozens of supplies starting from carbon fibre composites, metals and alloys to sand, tungsten filament, and bio-compatible supplies. Understandably, the functions and potentialities have additionally expanded manifold.

Trade 4.0 is gearing up to make use of additive manufacturing capabilities to print instruments and jigs, and end-use parts too. The power sector is utilizing additive manufacturing to print elements for customised options, whereas carmakers are utilizing it to customize luxurious automobiles. The aerospace world is utilizing it extensively to print light-weight however sturdy elements and parts from particular supplies, whereas the meals business is utilizing it to make customised confectioneries and personalised vitamin options.

| 3D Printing: A Fast Background |

| 3D printing, or additive manufacturing, is a expertise that has been creating slowly and steadily for the reason that Nineteen Eighties. In easy phrases, a 3D printer can take CAD file as enter and print a three-dimensional object by depositing layer after layer of an appropriate materials. Therefore, it is named ‘additive’ manufacturing. In some uncommon circumstances that require excessive precision, a subtractive course of may additionally happen, the place extra materials is shaved off the thing. Over time, a number of applied sciences have emerged, able to printing with completely different supplies, and with various levels of precision. Every era, or every new course of, goals to convey down the manufacturing time and prices, enhance the precision, and widen the spectrum of supplies that can be utilized. Now, supplies starting from gypsum and ceramic to wooden and titanium are getting used for 3D printing. Because of this, the potential functions are additionally rising. |

From building to electronics, everybody appears to be exploring how they’ll utilise the potential of 3D printing. Allow us to share a few of these insights.

Print a tablet? Previous information! Able to print organs now

In response to a report by Grand View Analysis, an India and the US based mostly market analysis and consulting firm, the worldwide healthcare additive manufacturing market dimension was valued at US$1.6 billion in 2021. It’s anticipated to develop at a compound annual development price (CAGR) of twenty-two.6% from 2022 to 2030. The necessity for customised medical tools like implants, the emergence of recent 3D printing applied sciences that may economically print complicated designs, and growth of recent biocompatible materials able to printing tissues, organs, dental fittings, orthopaedic and cranial implants are contributing to this development.

Medical tools like implants could be very costly to provide with conventional tools, moulds, dies, and all of the works. In any case, most of those are similar to artistic endeavors, tailored to suit an individual. On prime of that, these should be produced rapidly; generally it’s a matter of life and loss of life. The flexibility to swiftly develop prototypes utilizing computer-aided design (CAD) makes 3D printing quick and economical.

Serving to hand through the pandemic

3D printing rose to the event to assist healthcare methods through the Covid-19 pandemic. Lockdowns crippled provide chains, however there was a rising want for provides like private protecting tools (PPE). 3D printing lovers from world wide, college labs, and firms that had 3D printers began assembly this demand by printing items like face shields and valves for respiratory machines. For instance, 3T Additive Manufacturing Ltd and EOS produced greater than 100,000 face shields for healthcare staff within the UK. Allevi Inc, a 3D bio-fabrication firm, produced a mannequin of the lungs of an individual contaminated with SARS-CoV-2, which was studied by researchers on the Wistar Institute to know the situation and discover methods to deal with and forestall it.

Prosthetics and exoskeletons

Earlier this yr, 3D printing saved the lifetime of a child lady born with a critically-underdeveloped skull—in easy phrases, with out a cranium. A health care provider approached Sygnis, a Polish deep tech firm, simply hours earlier than the child was on account of be born. Armed with imaging information, Sygnis began 3D printing the cranium utilizing two completely different applied sciences, in case one failed. Inside a day, that they had the mannequin prepared—and the medical doctors accomplished becoming it inside 4 days. The newborn would require additional remedy as she grows, and hopefully tech will discover a means to assist her survive.

Not too long ago, Sygnis additionally produced one other pre-operative mannequin—the backbone of a younger little one with meningo-spinal hernia and scoliosis.

3D printing can also be proving to be very efficient within the manufacture of exoskeletons for rehabilitation. 3D-printed exoskeletons are lighter, extra sturdy, decrease in value, and an ideal match for the particular person.

| 3D Printing Know-how | Supplies | Functions |

| Sheet lamination strategies, resembling ultrasonic additive manufacturing and laminated object manufacturing | Paper, plastic, metallic, any sheet materials that may be rolled | Non-functional prototypes and fashions, multi-colour prints, casting moulds |

| Directed metallic deposition (DMD) or directed power deposition (DED) | Metals like cobalt, chrome, titanium | Repairing high-end parts, useful prototypes |

| Materials extrusion, commonest being fused deposition modelling (FDM) | Plastics and polymers, together with polylactic acid (PLA), polycarbonate, acrylonitrile butadiene styrene (ABS), nylon, polyetheretherketone (PEEK), thermoplastic polyurethane (TPU) and thermoplastic elastomer (TPE), carbon fibre filament | Digital housings, form-fitting fixtures, funding casting patterns |

| Materials jetting, nano-particle jetting, drop-on-demand | Plastics, polymers, silicone, metals | Prototypes, medical fashions, design displays |

| Binder jetting | Polymers, metals, ceramics, glass | Metallic elements, low-cost prototypes, sand casting moulds |

| Vat photo-polymerisation, resembling stereolithography (SLA), direct mild processing (DLP), and steady direct mild processing (CDLP) | Plastics, polymers, resins | Injection moulds, prototypes and fashions, dental fixtures, medical elements |

| Powder mattress fusion applied sciences, together with direct metallic laser sintering (DMLS), electron beam melting (EBM), selective warmth sintering (SHS), selective laser melting (SLM), and selective laser sintering (SLS) | Powder-based polymers and metals, together with nylon, PEEK, non-toxic plant-based resin, chrome steel, titanium, aluminium, cobalt, chrome, copper, Alumide (a composite of aluminium and nylon), and Inconel (an alloy of chrome and nickel) | Practical metallic elements, low-volume manufacturing, hole designs |

There are additionally some open supply initiatives, which purpose to make low-cost 3D-printed prosthetics out there to underserved populations internationally. Cyborg Beast, for instance, is a low-cost 3D-printed prosthetic hand for youngsters with upper-limb reductions. The designs can be found underneath a Inventive Commons license, so anybody can obtain, customise, and 3D-print them.

| 3D Printer in House |

| In response to a latest information report, aerospace firm Airbus is planning to ship a metallic 3D printer, Metal3D, to the Worldwide House Station (ISS) in 2023, as a part of its plans to determine an orbital satellite tv for pc manufacturing unit. In response to Airbus, this would be the first metallic 3D printer on the ISS. It should allow astronauts to print instruments and elements like radiation shields. The corporate additionally says within the media report that future variations of the printer will be capable of create objects out of lunar soil and recycle elements from decommissioned satellites onboard an orbital satellite tv for pc manufacturing unit. |

In response to the Biomechanics Division of the College of Nebraska Omaha, the vast majority of the required supplies can be found at native {hardware} shops or on-line, costing roughly US$50. It takes round 2.5 hours to assemble the prosthetic hand, which weighs lower than 200 grams. An analogous system (made utilizing conventional strategies) would value roughly US$4000 and weigh about 400 grams.

Blood vessels, tissues, and organs too

The rising area of 3D bioprinting includes printing with cells and biomaterials, creating organ-like buildings that allow dwelling cells multiply. These tissues and organ fashions assist to know diseased situations higher (for drug growth) and for potential remedy.

Scientists at Technion-Israel Institute of Know-how have created a hierarchical community of 3D-printed blood vessels able to supplying the required quantity of blood to an implanted tissue. For a tissue implant to achieve success, it should first be permeated by the physique’s blood vessels for it to obtain the required oxygen and vitamins. To attain this, the tissue is first implanted in a wholesome limb of the affected person’s physique, after which shifted to the required location. This complicates and delays the method.

At Technion, the scientists have created a tissue flap within the lab, with all of the vessels vital for blood provide, so it may straight be implanted within the affected space. The brand new tech has been efficiently examined on rats and will probably be examined on bigger animals earlier than it’s prepared for human use.

Whereas earlier experiments used collagen from animals within the bio-ink, right here, Israeli firm CollPlant Biotechnologies has genetically engineered tobacco crops with 5 human genes to provide collagen! In response to the researchers, massive blood vessels of the precise form vital might be printed and implanted along with the tissue that must be implanted. This tissue might be shaped utilizing the affected person’s personal cells, eliminating rejection danger.

A staff of researchers led by affiliate professor Dr Akhilesh Gaharwar and assistant professor Dr Abhishek Jain, within the Division of Biomedical Engineering at Texas A&M College, have designed a 3D-bioprinted mannequin of a blood vessel in wholesome and diseased states. They’ve additionally developed a brand new nanoengineered bio-ink, which has the power and optimum viscosity for easy printing. The ink is printed into 3D cylindrical blood vessels, consisting of dwelling co-cultures of endothelial cells and vascular easy muscle cells, which keep integrity of the arterial partitions.

One of the best half is that they’ve customised a US$200 off-the-shelf thermoplastic printer right into a bioprinter, saving hundreds of {dollars}. This scientific growth will assist in analysis, remedy, and growth of medication for cardiovascular ailments.

With calcium phosphate as materials, it’s now potential to print bones, which unify inside weeks after grafting, with low price of rejection by the physique. Fairly not too long ago, researchers at Princeton College 3D-printed a bionic ear with above-average listening to skills, demonstrating the opportunity of creating bionic organs by combining organic and nano-electronic functionalities by means of 3D printing.

Scientists and firms world wide have proven that it’s potential to 3D-print a number of elements of the human physique right now, from pores and skin to eye lenses and jaw bones. As well as, researchers are additionally investigating the opportunity of bio-ink infused with stem cells, which when injected in a scaffolding might assist an organ to develop or regenerate.

Personalised surgical devices

When in comparison with exoskeletons and organs, this may see much less implausible, however 3D-printed surgical devices are equally essential within the life-saving journey. With 3D printing, it’s potential to quickly prototype and develop personalised surgical devices at a really reasonably priced value level. Extremely miniaturised devices can be 3D-printed, serving to the surgeon to carry out extra exact surgical procedures. Firms like Formlabs and EOS are additionally into printing surgical devices.

Sowing the seeds of innovation in India

Very not too long ago, the Indian Institute of Science (IISc), Bengaluru, partnered with CELLINK—a worldwide chief in 3D bioprinting—to determine a Centre of Excellence (CoE) for 3D bioprinting in India. The CoE will probably be located on the Centre for Bio Programs Science and Engineering (BSSE) at IISc and can home a number of CELLLINK 3D bioprinters.

The Centre will present researchers with fast entry to 3D bioprinting methods, accelerating their efforts. It should additionally spearhead analysis and coaching initiatives associated to the functions of 3D bioprinting in fields like tissue engineering, drug discovery, materials science, and regenerative/personalised medication. There will probably be a particular deal with the guts, bone cartilage, and most cancers.

Mild and powerful elements for automobiles and crafts that fly

The automotive and aerospace industries have additionally recognised the advantages of 3D printing and began adopting the tech, particularly for low-volume, customised elements.

A Ford plant close to Cincinnati saved tens of millions of {dollars} by 3D printing a few costly and hard-to-get spares, like pucks and bumpers. A Normal Motors facility in Tennessee additionally skilled vital financial savings by changing standard tooling parts with 3D-printed options made in-house. The 3D-printed tooling had higher performance regardless of being developed quicker and at a decrease value.

The form of design freedom that 3D printing provides is a boon for carmakers, particularly within the luxurious section. Carmakers like Bentley are more and more turning to 3D printing to customize their choices and provides clients precisely what they need.

With 3D printing, auto-makers may also guarantee a correct provide of elements to clients, even those who went out of manufacturing years in the past. It is a dream-come-true for classic automobile and bike collectors, who at the moment are in a position to restore and protect their outdated fashions in working situation. Service centres in distant areas might additionally profit by the power to 3D-print spares as a substitute of ready for them to reach from faraway warehouses.

3D printing is an actual disruptor within the racing world, the place aerodynamically-optimised elements with the proper supplies and designs can clinch a win. It isn’t shocking that the majority racing specialists right now have partnered with 3D printing companies—Ducati Corse with Roboze, Alfa Romeo with Additive Industries, EOS with the Camozzi Group, NASCAR with Stratasys, and so forth.

A number of elements, starting from brake ducts, brackets and helps, to seals and cockpit air flow methods, are being 3D-printed right now. Materials innovation can also be at its peak on this area—new composites are giving these automobiles and bikes the correct mix of power, weight, and temperature tolerance.

If these elements are so essential for vehicles, you may simply think about how essential they might be for aircrafts and spacecrafts. No marvel then that the aerospace business is an keen taker for this tech. Additive manufacturing is getting used to print a number of stuff, from jigs and fixtures to surrogates, mounting brackets and detailed prototypes.

The tech helps engineers make lighter and extra environment friendly engines and turbine elements. The flexibility to print alternative elements reduces downtime and in addition extends the lifetime of aircrafts, as even out of date elements might be upgraded to present requirements and 3D-printed.

A Dassault Systèmes report remembers how Satair, an plane part and repair firm based mostly in Denmark and a subsidiary of Airbus, supplied one in every of its airline clients within the US with a 3D-printed spare half in 2020. The half was now not being produced by the unique provider. Redesigning it and producing it utilizing standard strategies was an costly proposition. So, utilizing a brand new certification course of, Satair was in a position to recertify the previous forged half inside 5 weeks and adapt it to titanium, a fabric well-suited for additive manufacturing and to be used in aircrafts. The half was then 3D-printed and provided to the clearly completely satisfied buyer!

Apparently, additive manufacturing is used extensively to print elements of cabin interiors like seats and handles—in an effort to cut back weight whereas sustaining aesthetics. Decreasing weight helps cut back air drag, saves gasoline, and correspondingly carbon dioxide emissions too.

The Peekay Group in affiliation with Bengaluru Airport Metropolis Restricted (BACL) has arrange a brand new state-of-the-art 3D printing facility on the Airport Metropolis. It has a manufacturing centre and an expertise zone, the place people and college students can come and check out their hand at 3D printing. It should additionally incubate worthy initiatives.

The Peekay Group additionally plans to put in a 3D metallic printing unit to cater to the aerospace business. They hope so as to add extra 3D printing processes, so college students can get extra expertise in environment-friendly, design-oriented manufacturing, whereas technicians may also upskill themselves.

Your constructing, as you prefer it, as quick as you need it

In April 2021, Tvasta Building, a startup incubated at IIT Madras, constructed a 56 sq. metre (600 sq ft) home on the college campus. The quaint home has a corridor, a kitchen, and a bed room. Sounds regular? Nicely, what makes it particular is that it was constructed inside 5 days utilizing concrete 3D printing expertise.

Extra not too long ago, the Indian Military’s Navy Engineering Providers (MES) partnered with Tvasta to 3D-print two homes for troopers on the South-Western Air Command, Gandhinagar, inside a month’s time. The 65 sq. metre (700 sq ft) properties are designed to be disaster-resistant and meet Zone-3 earthquake specs. In addition they 3D-printed sanitary blocks with a complete constructed space of about 56 sq. metres at Jaisalmer.

The startup works intently with the Central Constructing Analysis Institute and Structural Engineering Analysis Centre to make sure that the 3D-printed buildings meet required security requirements. However homes should not all that they’ll construct. They’ve even been requested to construct bunkers and parking services at border areas, the place conventional building is a problem because of the harsh climate and hostile situations!

Equally, the US Division of Defence (DoD) is constructing three coaching barracks in Texas utilizing 3D printing tech, with non-public partnership. Every barrack will probably be greater than 530 sq. metre (5700 sq ft) in dimension, making these the most important 3D-printed buildings within the US. It is going to be printed utilizing a proprietary high-strength concrete, able to withstanding the tough desert climate.

Again dwelling in Bengaluru, we hear that a whole three-storied put up workplace goes to return up in Halasuru inside a month or so. The undertaking will probably be accomplished utilizing 3D printing expertise by Larsen & Toubro Building at simply 25% of the traditional building value.

For jawans and inexperienced warriors, meals, and fundas

3D printing is discovering some use or the opposite in lots of fields, and it’ll not be lengthy earlier than these disparate functions unify into large-scale adoption.

Defence

Though 3D printing shouldn’t be broadly used for essential navy tools, it helps the military in some ways. We already examine housing, barracks, and bunkers being constructed utilizing 3D printing applied sciences.

3D printing can also be used to print armour fits, and elements utilized in plane engines, tanks, and submarines. Not too long ago, the US DoD introduced that it plans to pair defaulting suppliers with 3D printing corporations that may print metallic elements, to allow them to rapidly recover from the backlog.

Like in different industries, 3D printing can also be used extensively for prototyping and testing navy tools. The Indian military can also be collaborating with many Indian 3D printing corporations like Chennai based mostly Tvasta Constructions and Mumbai based mostly Divide by Zero.

Researchers at IIT Jodhpur have not too long ago developed a metallic 3D printer appropriate for repairing and including extra materials to current parts. It might probably print with metallic powders made in India and is taken into account ideally suited for printing fully-functional elements for aerospace, defence, automotive, oil, gasoline, and different industries.

Vitality

Advantages like design flexibility, quick time-to-market, lighter and higher performing elements, discount in materials wastage, elimination of supply-chain points, and tool-free manufacturing are main a number of corporations within the power sector to deploy 3D printing options. Most market leaders—together with BP International, Chevron, Exxon Mobil, GE Energy and Shell International—are utilizing 3D printing.

Earlier, 3D printing was used just for prototyping and never for end-use parts. However, with the power to print with extra supplies, it’s getting used to print varied items like photo voltaic panels. In response to a report by GE Analysis, 3D-printed photo voltaic panels have confirmed to be 20% extra environment friendly than conventional ones, and at half the worth of producing.

3D printing can also be used for manufacturing high-value, high-complexity, low-volume parts, like gasoline turbine nozzles, impellors, pistons, pumps, rotors, and elements for management valves, movement meters, warmth exchangers, and strain gauges. The price of downtime could be very excessive within the power sector and failure can happen even in distant areas. The flexibility to print spares will assist cut back downtime with out stocking up on spares.

Robotics

3D printing is a boon for robotics lovers in nations the place parts should not simply and economically out there. Since many part designs can be found on-line underneath free or open supply licenses, lovers with entry to 3D printers can simply print these parts and use them of their initiatives. Even when they’re unable to personal one individually, teams of lovers can pool in and share 3D printers.

The truth is, it’s this want that motivated the founders of Divide by Zero to drift a 3D printing startup. They used to enter a number of robotics contests once they have been in faculty and have been in hassle every time a robotic wanted a spare. No machine instrument store was able to manufacture one or two items and, even when they did, they used to cost them closely.

This motivated them to develop an indigenous 3D printer such because the Accucraft i250+. “We considered making reasonably priced 3D printers for the Indian market and assist people and organisations to prototype their concepts, play with them and create wonders,” mentioned one of many founders in an interview. The inherent advantages make 3D printing engaging to hobbyists and the business alike.

Openbot by Intel and Atlas by Boston Dynamics are a number of the well-known 3D-printed robots, to not neglect the rising vary of 3D-printed humanoids, swarms, amphibious and different bio-inspired robots. 3D printing of sentimental robots from non-toxic, gelatin based mostly materials is gaining reputation of late for functions like instructing and coaching kids, meals manufacturing, consumable biomedical check tools, and so forth.

3D printing plus Arduino is an all-time favorite combo of hobbyists, and you could find a number of robots starting from cute to chunky on Instructables and Thingiverse. Do take a look at the lovable dancing robotic Tito, the spider-like Hexapoduino, the useful MeArm V0.4, and extra such initiatives on-line.

Others

You eat the meals together with your eyes first, goes the adage. It’s subsequently not shocking that the meals business has been fast to select up 3D printing methods to create visually-appealing meals like by no means earlier than. 3D printing is used broadly to provide small batches of customised meals, and for creating personalised vitamin packages.

3D printing can also be a beautiful studying instrument. Around the globe, faculties and schools are utilizing 3D printing to print a variety of fashions from historic monuments to useful elements, to assist college students perceive ideas higher.

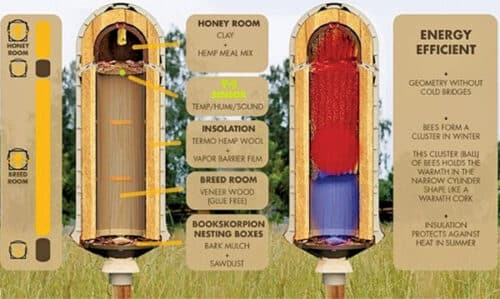

It is usually discovering revolutionary makes use of in farms. In Germany, for instance, a startup referred to as HIIVE is 3D printing tree cavities for bee farms. Honeybees just like the Apis Mellifera initially dwell in tree cavities, which have a particular microclimate that isn’t solely good for bees but in addition for helpful symbionts that co-inhabit the tree cavities with the bees.

Utilizing a close-to-natural hive, bee farms can entice extra bees, and get a greater harvest, whereas additionally guaranteeing a pure habitat for the bees. A symbiotic deal certainly. 3D printing made it potential for HIIVE to iteratively tweak the design to develop an optimum construction for the tree cavities, that are 3D-printed with a number of pure supplies.

3D printing additionally permits a number of innovation and optimisation within the electronics business. Speedy prototyping and the power to fabricate small batches of electronics at a decrease value is a boon for all consuming industries. 3D printing can also be mentioned to be extra eco-friendly, because it generates a lot much less e-waste as in comparison with the normal etching processes. The flexibility to print on non-flat surfaces and on diverse supplies, together with plastics, opens up new alternatives for innovation.

House Foundry, an organization launched by former NASA researcher Ram Prasad Gandhiraman and Dennis Nordlund of Stanford College, has created a plasma based mostly 3D printing course of, which may print electronics in a single-step strategy that doesn’t require warmth or ultraviolet curing. The multilateral printing platform can print varied supplies, together with metals like copper, dielectrics, organics and even bioinks. It’s an environment-friendly course of that doesn’t go away behind liquid industrial waste or poisonous by-products.

NASA believes this tech can improve its in-space manufacturing efforts by means of on-demand manufacturing of electronics (ODME), as plasma jet printing can probably be used for manufacturing within the low Earth orbit and on the lunar floor. In a press report, Gandhiraman describes their 3D printer as a extremely miniaturised model of semiconductor manufacturing expertise.

As a service

Whereas we do see random use of 3D printing in nearly all industries, it’s but to realize traction in mission-critical functions, as certification and half qualification processes are nonetheless not in place. For fast prototyping and testing, or for one-off manufacturing wants, it doesn’t make sense for small corporations to spend money on 3D printing setups. Nonetheless, everybody can be completely satisfied to have a go at it, if out there as a service. There are various corporations providing 3D printing as a service, and that is prone to stay the favored selection within the close to future too.

| 3D Printer in House |

|

In response to a latest information report, aerospace firm Airbus is planning to ship a metallic 3D printer, Metal3D, to the Worldwide House Station (ISS) in 2023, as a part of its plans to determine an orbital satellite tv for pc manufacturing unit. In response to Airbus, this would be the first metallic 3D printer on the ISS. It should allow astronauts to print instruments and elements like radiation shields. The corporate additionally says within the media report that future variations of the printer will be capable of create objects out of lunar soil and recycle elements from decommissioned satellites onboard an orbital satellite tv for pc manufacturing unit. |

3D printing good for Atmanirbhar Bharat

Recognising the scope of 3D printing, the Ministry of Electronics and Info Know-how (MeitY) launched the Nationwide Technique for Additive Manufacturing earlier this yr. The ministry hopes to extend India’s share within the world additive manufacturing to five% by 2025. The nationwide technique units varied objectives for the business on this route—so as to add US$1 billion to the gross home product; develop 50 India-specific applied sciences for materials, machine and software program; setup 100 new start-ups for additive manufacturing; develop 500 new merchandise; prepare no less than 100,000 new expert staff, and so forth, within the subsequent three years.

The technique recommends that India should come forth and undertake additive manufacturing in all sectors, together with defence and public sectors. Adoption of 3D printing on an industrial scale might assist home corporations to beat technical and financial obstacles—and tread proudly on the trail of a self-reliant India!

Janani G. Vikram is a contract author based mostly in Chennai, who loves to put in writing on rising applied sciences and Indian tradition. She believes in relishing each second of life, as completely satisfied reminiscences are the most effective financial savings for the longer term