Chipmaker Micron Know-how introduced in the present day it’ll spend $20 billion to construct what it known as the largest-ever US semi-conductor manufacturing unit, and it might spend as much as $100 billion over 20 years to broaden it.

The fabrication plant, to be positioned in Onondaga County, New York, would be the dimension of 40 US soccer fields and is predicted to offer near 50,000 jobs for the area, together with “9,000 excessive paying Micron jobs.” As soon as accomplished, the manufacturing facility is predicted to drastically improve the home provide of reminiscence chips.

Micron’s announcement follows different US semiconductor manufacturing unit tasks made not too long ago by different chipmakers, together with Intel, Samsung, and TSMC. The brand new fabs are all a part of an effort to revive chip and different expertise manufacturing to US shores.

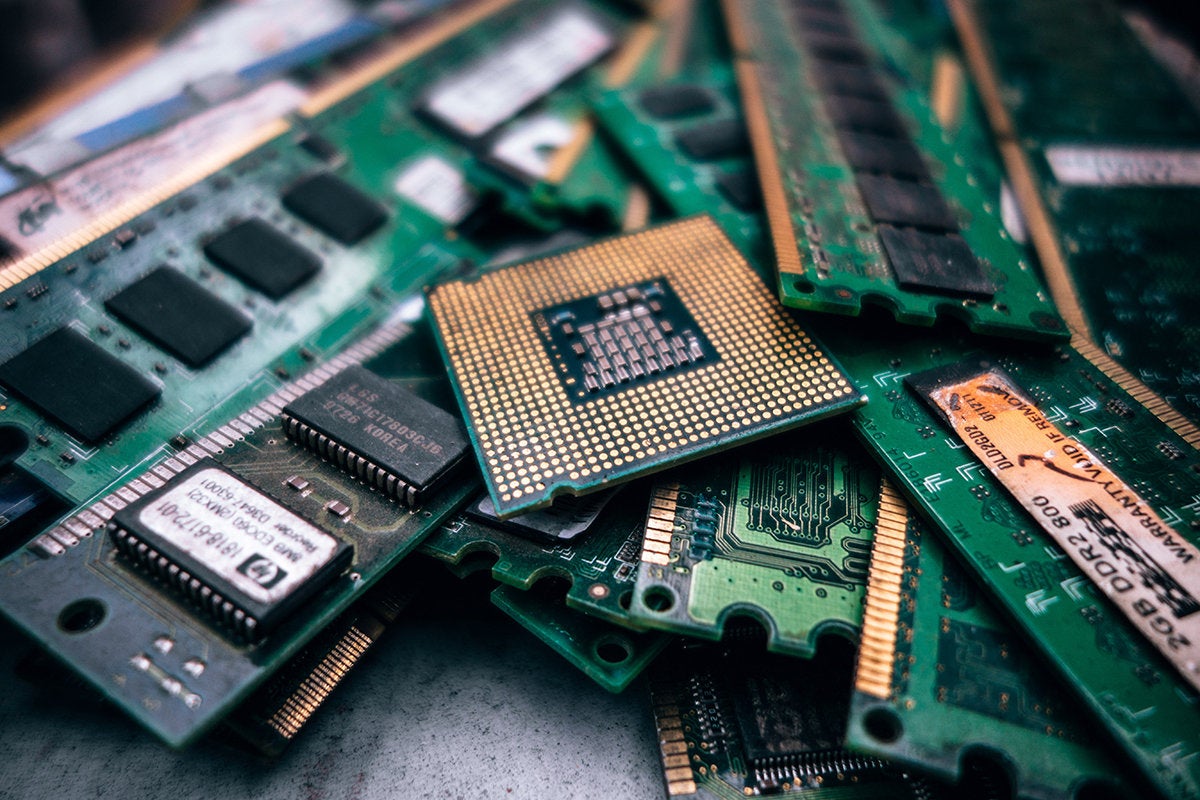

Fancycrave (CC0)

Fancycrave (CC0)In September, Micron broke floor on a reminiscence manufacturing fab close to its headquarters in Boise, ID. That plant was Micron’s first new reminiscence manufacturing facility within the US in 20 years. Micron additionally not too long ago introduced plans to speculate roughly $15 billion by the tip of the last decade in superior reminiscence manufacturing in Boise, the biggest non-public funding ever made within the state, in keeping with the corporate. The fabrication plant follows Micron’s earlier announcement to make investments $40 billion by the tip of the last decade to determine modern reminiscence manufacturing within the US.

In a press release, Micron President and CEO Sanjay Mehrotra thanked President Joe Biden and members of Congress for passing the $50 billion CHIPS and Science Act, which was signed into legislation in August. The Act is aimed at revitalizing the home semiconductor manufacturing {industry} within the US, which has seen its market share slip drastically lately attributable to excessive operational prices in comparison with its East Asian competitors.

Whereas different elements, together with geopolitics and techno-nationalism, are enjoying a giant function within the reshoring of semiconductor manufacturing, the CHIPS ACT is “the ultimate motivation” as funds, subsidies, and tax breaks “present a stage enjoying discipline the place fabs within the US may be value aggressive with these in Asia,” mentioned Gaurav Gupta, Gartner’s vp for Rising Applied sciences and Tendencies.

Micron will get $5.5 billion in incentives from the state of New York over the lifetime of the venture, alongside anticipated federal grants and tax credit from the CHIPS and Science Act to help hiring and capital funding.

Whilst main semiconductor producers transfer ahead with plans to construct new fabrication services within the US, creating tens of 1000’s of recent jobs, a lack of obtainable tech expertise threatens to stymie efforts.

“The competitors for expertise is fierce,” Cindi Harper, vp of Human Sources, Expertise Planning and Acquisition at Intel, mentioned in an earlier interview with Computerworld. “It’s additionally a candidate’s market, that means the demand for expertise is bigger than the present provide.”

Gupta famous that discovering expert employees will probably be a battle, although there are a variety of college applications being sponsored by chipmakers — even in group faculties — to develop a piece power.

“After all, the CHIPS ACT additionally has some provisions for it — workforce improvement,” Gupta mentioned. “Now that chip manufacturing is type of coming again, college students and younger engineers and technicians could have the motivation to look in direction of this discipline.”

Micron and the state of New York mentioned they’ll spend $500 million in group and workforce improvement with a give attention to deprived populations over the period of the plant building.

Even so, chipmakers should compete with hyperscalers and software program makers who pays extra, “however, hopefully authorities subsidies will assist,” Gupta mentioned.

“I believe this will probably be a piece in progress,” he mentioned. “Fabs will come on-line between 2024 and 2030 and most of them are extremely automated. You do want building employees initially, however operational and employees necessities aren’t too excessive.”

Micron mentioned it selected the New York web site based mostly on the area’s larger schooling establishments, entry to expertise “historically underrepresented” in tech jobs and a big navy inhabitants that the corporate mentioned will align with its with dedication to hiring veterans. The area additionally has obtainable water sources and clear, dependable energy for a venture of this scale.

Website preparation will begin in 2023, building will start in 2024 and manufacturing output will ramp up within the latter half of the last decade, progressively rising consistent with {industry} demand, Micron mentioned.

“Finding Micron’s industry-leading DRAM manufacturing within the US brings great advantages for its clients, enabling them to construct their progressive merchandise and options utilizing a extra resilient, safe and geographically various provide chain,” the corporate mentioned in its assertion.

The fabrication plant may finally embody 4 600,000-square-foot cleanrooms, for a complete of two.4 million sq. toes of cleanroom house.

Micron aimsuse 100% renewable electrical energy on the plant and plans to depend on inexperienced infrastructure and “sustainable constructing attributes” for building of.

“Greenhouse gasoline emissions (GHG) for the brand new facility will probably be mitigated and managed through the use of state-of-the-art expertise. These efforts help Micron’s international goal to realize a 42% discount in GHG emissions from operations by 2030 and net-zero emissions by 2050,” the corporate mentioned.

Copyright © 2022 IDG Communications, Inc.