Researchers from Washington have demonstrated that 3D laser printing can be utilized to assemble advanced polymer optical gadgets straight on the top of an optical fiber

Conventional microscopic gadgets are costly and hulking. To switch this, researchers invented a micro-optical gadget utilizing 3D printing that consists of particulars smaller than the diameter of a human hair. This gadget would supply a really compact and cheap solution to implement mild beams for a wide range of purposes.

“Communication applied sciences, the web, and lots of different purposes are based mostly on optical fibers,” stated analysis group chief Shlomi Lightman from Soreq Nuclear Analysis Heart in Israel. “When the sunshine comes out of the fiber, giant cumbersome optical parts are sometimes used to route it to the subsequent location. Our strategy minimizes each the dimensions and price for this course of by integrating the routing course of into the fiber itself.”

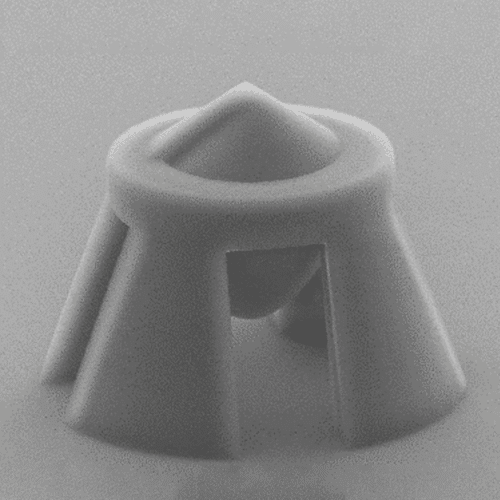

Researchers carried out 3D direct laser printing as a fabrication approach. The method makes use of a laser beam with femtosecond pulses to create two-photon absorption in photosensitive optical materials. They utilized a industrial 3D direct laser writing system and a excessive optical high quality photosensitive polymer to print a 110-micron-tall optical gadget 60 microns in diameter and 110 microns tall on the top of a single mode optical fiber solely after cautious evaluation of outcomes based mostly on simulations. The gadget consists of a mix of each a parabolic lens for mild collimation and a helical axicon lens that twists the sunshine. This converts mild exiting the fiber right into a twisted Bessel beam.

“The flexibility to create a Bessel beam straight from an optical fiber might be used for particle manipulation or fiber-integrated stimulated emission depletion (STED) microscopy, a method that produces super-resolution photographs,” stated Lightman. “Our fabrication methodology is also used to improve a cheap lens to a better high quality sensible lens by printing a wise small construction on it.”

Researchers experimented with the optical gadget to look at its high quality by constructing an optical measuring system to seize the formed beam propagating from the modified fiber. They famous very low diffraction within the beam, which signifies that it might be helpful for purposes like STED microscopy and particle manipulation. In addition they observed that the laser energy might attain near 10 MW/cm2 earlier than damaging the fabricated micro-optical gadget. This confirmed that even when the gadget was constituted of polymer, which is extra vulnerable than glass to warmth harm from excessive powers, it might produce comparatively excessive laser energy.

Even when this 3D direct laser printing is used beforehand, it’s tough to right the dimensions and alignment when fabricating such small optics on a fiber tip. “We had been in a position to overcome this hurdle by performing extremely correct 2D and 3D simulations earlier than we started the fabrication course of,” stated Lightman. “As well as, we needed to fastidiously take into consideration integrating the optical parts after which aligning that with the fiber core.”

Click on right here for the Revealed Analysis Paper