What it’s essential to know

- First 1000 Orders of Kobra Go get it for $189 as an alternative of $219

- 220x220x250 construct quantity

- PEI flex plate as customary

- Inflexible mounted mattress with automated levelling

In its seemingly endless endeavour of releasing a 3D Printer at each worth level, Anycubic is again with the brand new Kobra Go, a reasonable 3D Printer that really has some options you may want to try, such because the detachable magnetic flex plate, the LevIQ mattress levelling sensor and the return of the clicking wheel and non-touch LCD.

Beginning with the construct quantity, Anycubic has caught with the usual “ender 3” construct quantity of 220x220x250mm right here, which is okay, nevertheless, I’d have thought with the phrase “Go” within the identify, this may be positioned as a extra transportable printer, through which one thing a bit smaller, like 180x180x180mm, would have been chosen, and likewise allowed them to scale back the value much more. In contrast to conventional Ender 3 beds although, there aren’t any springs and retention screws holding the mattress down so that you can manually tram, as an alternative the mattress is rigidly screwed to the mattress carriage and all the remaining is finished in software program, one thing that we as a group have been asking for for some time.

Anycubic has additionally taken the initiative to position a powder coated PEI spring metal sheet because the mattress. Most cheap 3D printers use skinny, floppy fridge magnet like beds, or inflexible items of glass with a coating on prime. The flex plate means that you can take away the mattress from the printer with out worrying about damaging both the mattress, the printer or the 3D print itself, and because the identify implies you’ll be able to flex the sheet to assist within the print elimination, it additionally occurs to be very satisfying.

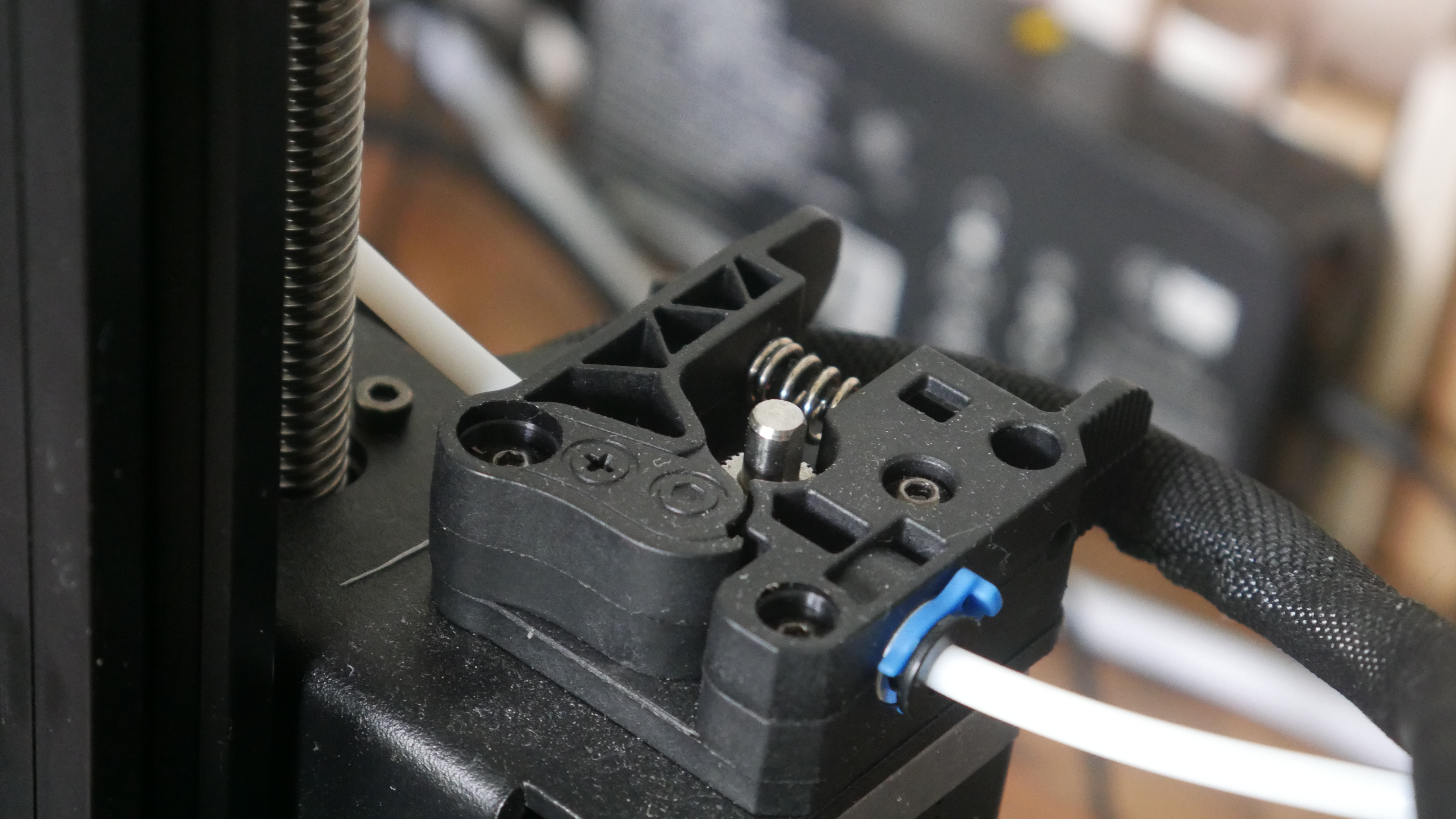

The remainder of the printer is a quite simple machine in the easiest way doable, there’s a customary single gear extruder related to the hotend by way of a PTFE tube, the outlet spacing of the hotend and the extruder are customary sizes, that means upgrades like an E3D Revo CR hotend or a Bondtech BMG extruder are easy to do should you wished, And the display screen is a small color LCD with a rotary encoder as an alternative of a touchscreen, paying homage to the older days of 3D Printing, however one thing I truly desire to touchscreens in lots of circumstances.

So how is Anycubic capable of supply a inflexible mount mattress, a textured PEI flex plate, automated mattress levelling and customized injection moulded elements for lower than the price of a Creality Ender 3 V2? fairly merely it comes much less assembled than its rivals, and I believe that could be a nice trade-off.

As a substitute of coming in 2 elements that you just connect along with 4 screws within the base that may take quarter-hour to assemble totally. The Kobra Go is available in many extra items, you will want to make the X-axis gantry, in addition to the Z-axis help. All in all of the Kobra Go will take about an hour to place collectively should you take your time and browse the directions.

For some, this is perhaps daunting and never value it, they might wish to spend the $299 for the truth Ender 3 V2 Neo, a printer with the identical construct quantity, a flex plate, automated mattress levelling and a bigger display screen, however comes largely assembled. Nevertheless, the Kobra Go technique of giving the consumer extra options, however having them do extra meeting is one which I believe will work in Anycubic’s favour.

As of as we speak, you should purchase the Kobra Go from Anycubic’s web site for $189 (opens in new tab), however solely the primary 1000 orders get it for that worth, after the early chook worth the Kobra go turns into $219, which continues to be an extremely good worth for this printer.