Copper and aluminum can deliver photovoltaic manufacturing nearer to the round financial system, bettering environmental and social requirements.

The rising worth and low availability of uncooked supplies are resulting in larger prices in producing photovoltaic modules. Researchers at Fraunhofer Institute for Photo voltaic Power Programs ISE have developed which replaces silver with copper for the electroplating course of utilized in manufacturing of photo voltaic cells.

The areas with electrically conductive areas don’t require full electroplating with copper and therefore first have to be masked. These areas are lined utilizing an electrically insulating impact which prevents it from being electroplated. The copper layer will solely construct up within the areas not coated with the insulation.

One other vital development made right here is that costly polymer-based lacquers or laminated foils have been changed with aluminum. Switching the supplies twice, from silver to copper and from polymer to aluminum, additionally brings twice the profit: Producing photo voltaic cells shouldn’t be solely extra sustainable, but additionally considerably cheaper.

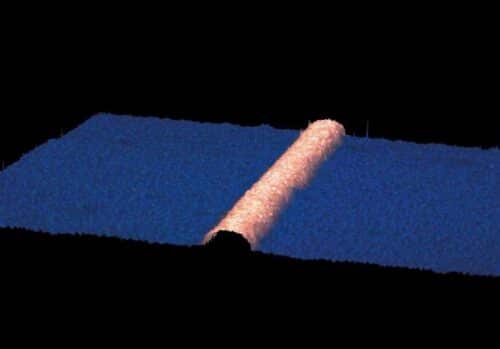

“We developed a particular electroplating course of that makes it potential to make use of copper as a substitute of silver for the busbars,” explains Dr. Markus Glatthaar, an knowledgeable in metallization and structuring. Because of the copper line’s’ extraordinarily small width of solely 19 μm (micrometers), the light-absorbing silicon layer experiences much less shading than with the silver traces. This and the excessive conductivity of electroplated copper enhance the electrical energy yield.

The second technological achievement made by the Fraunhofer staff is utilizing aluminum as a masking layer. However an issue right here is that the electrically conductive nature of aluminum, which renders it at first look unsuitable to make use of as a masks. Researchers took benefit of the truth that aluminum can kind an insulating oxide layer on its floor. “We have been in a position to adapt the method parameters and develop a particular kind of electrolyte which ensures that the aluminum’s extraordinarily skinny, native oxide layer can reliably fulfill its insulating operate. This was an necessary milestone for the success of our analysis undertaking,” Dr. Glatthaar is happy to report.

Copper and aluminum each being recyclable supplies can deliver photovoltaic manufacturing a lot nearer to the round financial system, bettering environmental and social requirements within the course of. “Provided that we’ve adequate provides of copper in Germany, the provision chains are a lot shorter and the value is much less depending on worldwide uncooked materials markets or overseas suppliers,” provides Dr. Glatthaar.