Engineers design fluidic logic parts into clothes to assist folks with useful limitations carry out duties with out digital help.

Engineers at Rice College have designed textile-based pneumatic computer systems able to digital logic, onboard reminiscence and person interplay. The idea works on how air flows via a sequence of “kinked” channels to kind bits, the 1s and 0s in laptop recollections. The concept is to reap power from a textile primarily based logic gates that assist pneumatic actuators.

“The concept of utilizing fluids to assemble digital logic circuits is just not new,”mentioned Daniel Preston, Assistant Professor at Mechanical Engineering Division Rice College. “And in reality, within the final decade, folks have been transferring in the direction of implementing fluidic logic in tender supplies, issues like elastomers. However to date, nobody had taken the step to implement it in sheet-based supplies, a feat which required redesigning your entire strategy from first rules.”

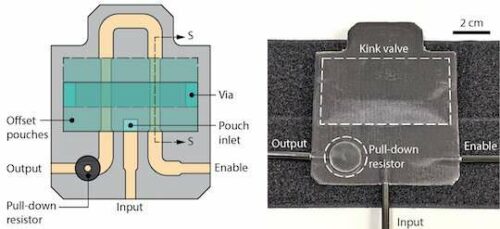

An inverter, principally a ‘NOT’ gate, sits on the middle of the idea. The pneumatic gate works with “excessive” or “low” air stress, the identical as in a gate, on or off(1 or 0). “We consider the logic ingredient as, at its most basic degree, containing each a relay and a fluidic resistor,” mentioned Anoop Rajappan, a Rice postdoctoral fellow and lead creator of the paper. “These can be equal to having an digital relay or transistor paired with the resistor, which is the inspiration of typical transistor-resistor logic.”

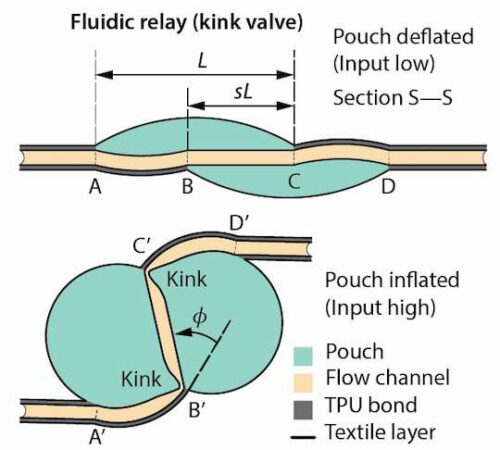

The pressure-controllable valves within the pneumatic system work on a mathematically designed kink geometry as described by Preston. These stress controllable valves lower the stream of air the identical approach a bent backyard hose stops water. These valves can deal with 20,000 on-off cycles and 1 million flex cycles, in addition to 20 cycles in a typical family washer.

The system is aimed to assist folks with useful limitations with their day-to-day duties.