Capacitors are widespread passive parts in all digital gadgets, together with automobiles. The utilization of capacitors in automobiles is predicted to extend within the coming years as electrical automobiles (EVs) achieve reputation. It is very important choose capacitors correctly with the intention to fight widespread points that happen in vehicular circuitry

Vehicular techniques at present have turn into vastly superior. Good vehicles, self-driving vehicles, electrical automobiles, and so forth are quickly gaining reputation not solely among the many rich but additionally among the many middle-class society. Because of the massive growth of innovation on this discipline, there’s a want for higher and extra sturdy digital elements, each passive and energetic.

Capacitors are extensively used within the automotive trade. The truth is, they’re essential to the functioning of a car. They supply stability and are used within the administration of present within the car’s circuitry. They’re additionally used to make sure that the design is free from interference. Capacitors play a significant position in braking techniques, window wipers, seat aligners, airbag controllers, and plenty of different necessary purposes inside a car.

Capacitors are extensively used within the automotive trade. The truth is, they’re essential to the functioning of a car. They supply stability and are used within the administration of present within the car’s circuitry. They’re additionally used to make sure that the design is free from interference. Capacitors play a significant position in braking techniques, window wipers, seat aligners, airbag controllers, and plenty of different necessary purposes inside a car.

Capacitors in EVs

Pushed by issues about petrol costs, authorities environmental initiatives, and large-scale private and non-private funding within the supporting charging infrastructure, the electrical car (EV) sector is present process a interval of considerable progress. Over the course of the following decade, the automotive market is ready to transition from being dominated by inside combustion engine (ICE) automobiles to 1 the place EVs make up the vast majority of new car gross sales.

ICE automobiles have relied on 12V and 24V powertrain architectures, with hybrids usually being based mostly on 48V techniques. EVs, nevertheless, have powertrains which are positioned at far greater voltages. Additional, with the intention to speed up cost instances and enhance conversion efficiencies, the voltages are being pushed even greater. The brand new EV fashions which are simply beginning to seem in the marketplace have 800V powertrain scores!

ICE automobiles have relied on 12V and 24V powertrain architectures, with hybrids usually being based mostly on 48V techniques. EVs, nevertheless, have powertrains which are positioned at far greater voltages. Additional, with the intention to speed up cost instances and enhance conversion efficiencies, the voltages are being pushed even greater. The brand new EV fashions which are simply beginning to seem in the marketplace have 800V powertrain scores!

For the primary time, worldwide EV annual gross sales surpassed 6 million models in 2021. Predictions made by the Worldwide Vitality Company (IEA) recommend that that is only the start. It forecasts that gross sales could have reached 15 million by 2025 and 25 million by 2030. The powertrains of EVs have to assist greater voltage ranges in comparison with their ICE counterparts, and this may have main implications relating to specifying constituent passive elements.

Even for 48V hybrid techniques, the motors shall be situated on the powertrain itself. This does, nevertheless, imply that the accompanying electronics shall be uncovered to extra intense vibrations and thermal biking. Elements like vibrations, shock, and stress have clear results on the passive elements current within the system. Due to this fact, automotive engineers should take a look at the consequences this may have on element reliability.

ESR: An necessary parameter

A key efficiency parameter for any DC-Hyperlink capacitor shall be its equal collection resistance (ESR) worth. The decrease the ESR of a capacitor, the better its capability to clean out high-frequency voltage disturbances passing by the powertrain. If the ESR values that these capacitors current inside the electrical circuitry enhance as a result of some type of injury, the entire powertrain operation may doubtlessly be jeopardised.

Whereas choosing capacitors that conform to those elements, car producers should maintain the general bill-of-materials expense as little as attainable, so the chosen capacitors need to be cost-effective. There’s, subsequently, a continuing tradeoff between effectivity and value, and engineers want to take care of either side of the equation for the car to be optimum.

Whereas choosing capacitors that conform to those elements, car producers should maintain the general bill-of-materials expense as little as attainable, so the chosen capacitors need to be cost-effective. There’s, subsequently, a continuing tradeoff between effectivity and value, and engineers want to take care of either side of the equation for the car to be optimum.

Impact of car vibrations and stress

The adoption of excessive voltage ranges in EVs and the situation of motors away from the safety of the engine compartment in a number of hybrid techniques could have implications for the DC-Hyperlink capacitors included into EV and hybrid powertrains. Located between the battery and the traction inverter, these passive elements are used to clean out the voltage and forestall undesirable transient spikes from occurring. If they’re to be efficient, a excessive diploma of robustness is required. This may enable them to deal with the difficult utility setting that automotive deployment represents.

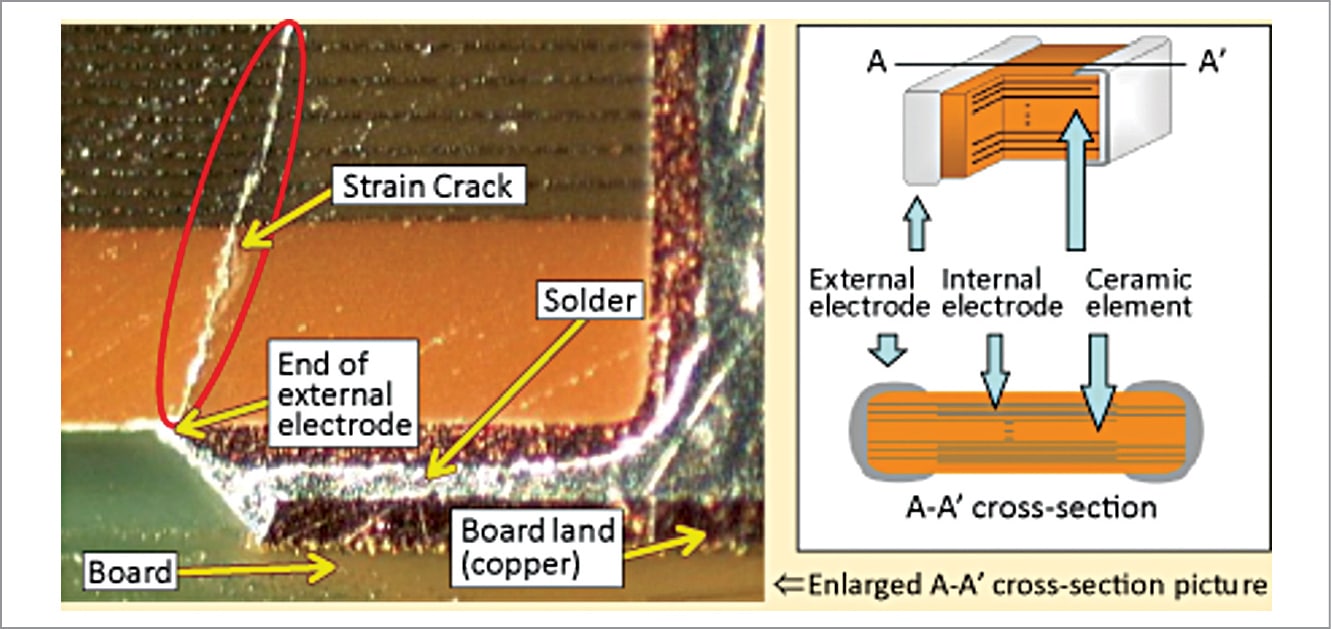

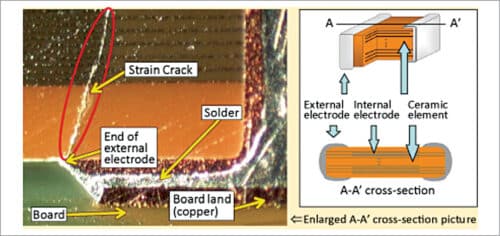

Normal multilayer ceramic capacitors (MLCCs) will not be effectively suited to automotive utilization, as they aren’t in a position to deal with the acute mechanical stresses concerned. If the PCB on which they’re mounted flexes, as a result of both vibration or thermal biking, the solder joints shall be positioned beneath appreciable pressure. This will result in cracks showing inside the ceramic substrate. These cracks can lead to moisture ingress arising which is able to, in flip, impression the capacitor efficiency. If these elements are situated near the sting of the PCB, the stresses that they’re subjected to are prone to be even better.

Combating vibration-related points

The vibrations witnessed in an car can come from a wide range of sources and be at a variety of various frequencies. Although these points are intrinsic in car design, they are often mitigated in quite a few methods as follows:

Specify polymer capacitors as an alternative of MLCCs

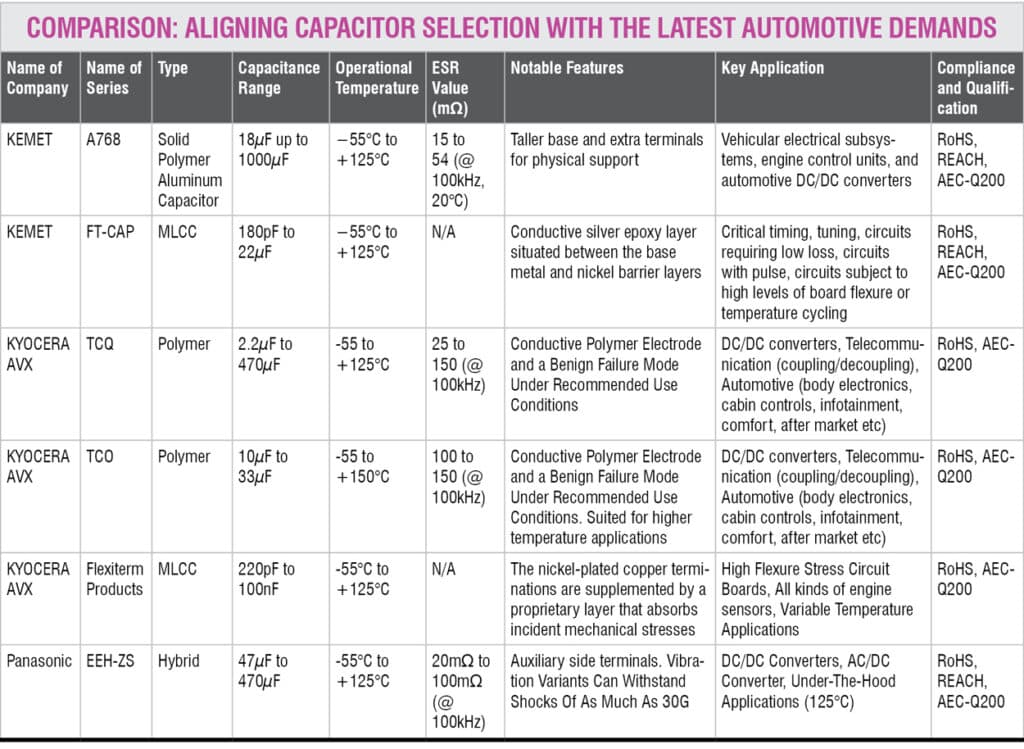

In contrast to regular capacitors whose electrolyte is definitely a liquid—a conductive answer—polymer capacitors have a stable electrolyte that’s made up of conductive polymers. They’re subsequently extra compact and there’s no likelihood of leakage or the capacitor drying out. These elements could have decrease ESR values than MLCCs, with higher efficiency throughout a variety of working situations. Nonetheless, there are elevated prices concerned.

A fantastic instance for this class could be Kemet’s stable polymer aluminium capacitor. It’s the stable polymer that makes these capacitors vibration-resistant. Of their A768 collection of stable polymer capacitors, a number of design modifications have been made to extend their vibration tolerance even additional. They have been supplied with a taller base for higher bodily assist. What’s attention-grabbing about these capacitors is that they’ve additional terminals that don’t present electrical conductivity however are literally used to present the capacitor a steady connection to the PCB.

Kyocera AVX has two particular collection of automotive polymer capacitors: the TCQ collection and the TCO collection. TCQ is used for normal temperature situations whereas TCO is used for purposes that demand greater temperatures. Each of those meet all of the ‘AEC-Q200 Stress Check Qualification for Passive Elements’ necessities and are dependable for a variety of temperatures. They’re strong and supply steady efficiency with a low ESR.

Utilizing hybrid capacitors

These comprise an anode with a liquid and conductive polymer building, alongside a cathode comprised of aluminium. The massive floor space of the liquid permits elevated capacitance values to be achieved in a compact kind issue. Just like the earlier choice, this comes with added prices.

The EEH-ZS hybrid collection of capacitors from Panasonic significantly goal automotive purposes and have vibration-resistant properties. These have auxiliary facet terminals that improve their vibration resistance. That is why these capacitors can face up to shocks with vibration acceleration as much as 30G. Additional, the facet terminals make soldering simpler. Whereas utilizing these capacitors, designers could select to not deploy exterior anti-vibration strategies. These are additionally RoHS/REACH compliant and qualify the necessities set by AEC-Q200.

Utilizing vibration-resilient MLCCs

In MLCCs, it’s attainable to make sure enhancements to the strategies by way of which the capacitor physique and its terminations are interconnected with each other in order that the vibrational forces skilled are dampened. On this method, extra prices of utilizing polymer or hybrid capacitors might be prevented. This allows better mechanical robustness to be attained, whereas nonetheless benefiting from the fee benefits of MLCCs.

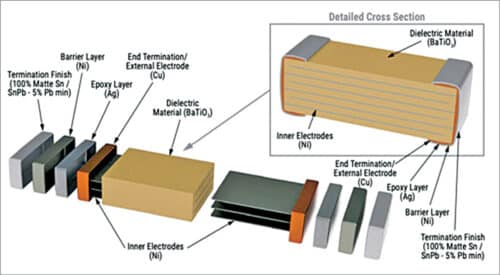

To handle the necessity for capacitors which are in a position to withstand vibrational forces, Kemet developed its FT-CAP collection. These MLCCs have an revolutionary termination association that helps to decrease the pressure imparted from the PCB when it’s flexed. A conductive silver epoxy layer is included within the termination construction (located between the bottom steel and nickel barrier layers). This allows terminal power to be upheld however offers the cushioning crucial to stop any cracks from showing. The capacitor’s continued efficiency is thus assured.

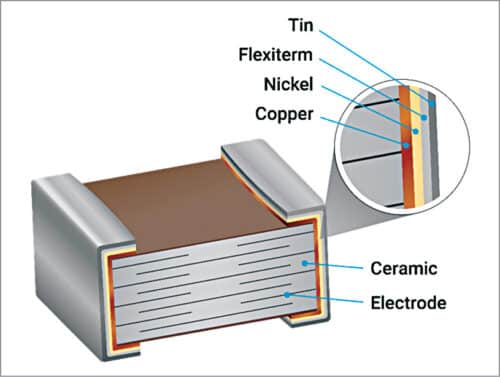

Kyocera AVX can also be tackling the vibration points beforehand outlined by its Flexiterm low ESR MLCC merchandise. These even have versatile terminations fitted to them for added elasticity. Right here nickel-plated copper terminations are supplemented by a proprietary layer that absorbs incident mechanical stresses. The producer has efficiently managed to do that with out there being any main enhance within the prices concerned. They assist an -55°C to +125°C operational temperature vary and 5mm flexes might be comfortably dealt with by them (in comparison with the 2mm that MLCCs are usually rated for).

A comparability of the capacitors talked about above is given within the Desk.

There are numerous capacitor collection developed by different producers to fight particular points, not solely vibration. They leverage engineering advances that present enhanced ranges of ruggedness. For instance, the PCZ collection launched by Nichicon Corp. has a terrific diploma of warmth resistance.

The automotive trade locations exacting calls for on the digital {hardware} employed in car designs, and the following technology of car fashions (significantly these which are EV or hybrid) will solely exacerbate this. Excessive voltage ranges will name for capacitors which have superior efficiency traits. These elements might want to face up to heavy vibrations, as an example, as they’re now being positioned into tougher environment. Which means automotive engineers want to pick out their elements correctly to be assured of long-term reliability even beneath the harshest of working situations.

This function is impressed by an article authored by the technical content material crew at TME. The co-author, Aaryaa Padhyegurjar, is an Business 4.0 fanatic with a eager curiosity in innovation and analysis.